When it comes to workplace safety, ensuring machinery is equipped with reliable safety circuits is critical. Occupational Safety and Health Administration (OSHA) guidelines emphasize the importance of using control reliable safety circuits to protect workers from hazards during machine operation. In this article, we’ll explore the basic OSHA requirements for implementing a control reliable safety circuit and how to ensure your facility complies with these standards.

What is a Control Reliable Safety Circuit?

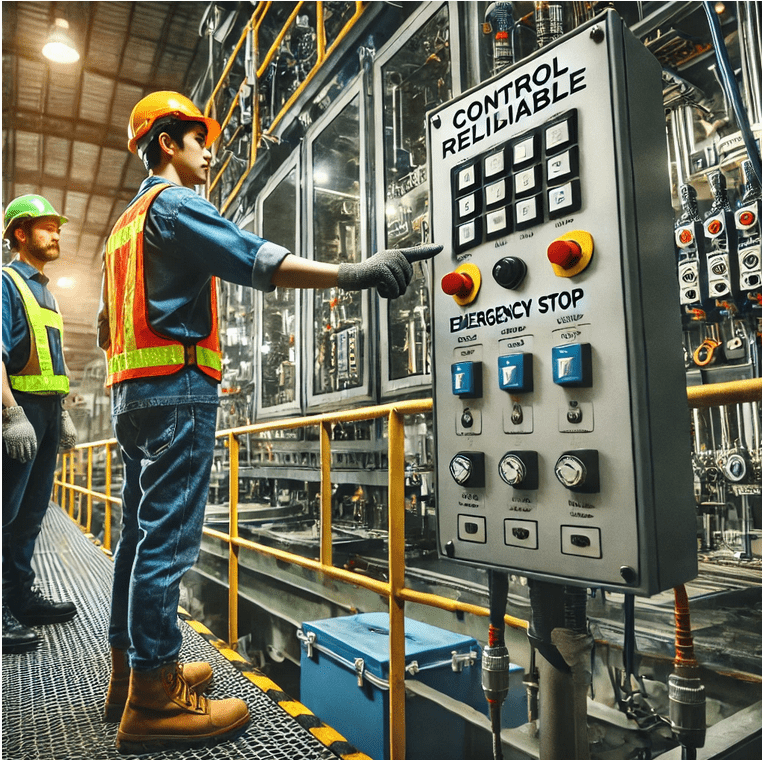

A control reliable safety circuit is a system designed to maintain safe operation of machinery, even in the event of a component failure. It ensures that if one part of the circuit fails, the machine enters a safe state, preventing hazards such as unintended startup or movement. The circuit often includes components such as emergency stop buttons, safety relays, and sensors to monitor machine conditions and stop operations when necessary.

OSHA’s Focus on Safety Circuit Reliability

OSHA standards are primarily concerned with minimizing workplace hazards, particularly those related to heavy machinery. Control reliable safety circuits align with OSHA’s goal by offering layered protection. According to OSHA’s machine guarding standard (29 CFR 1910.212), employers must ensure that all machines and equipment have adequate safety measures to prevent accidents.

Although OSHA does not mandate the use of a specific type of control circuit, it stresses that safety circuits must meet specific performance criteria. Key guidelines related to control reliable safety circuits include:

- Risk Assessment: OSHA recommends conducting a risk assessment to identify potential hazards associated with machinery. The risk assessment should guide the design and implementation of safety circuits, ensuring they are adequate for the identified risks.

- Redundancy and Fault Detection: To meet OSHA requirements, control reliable safety circuits must be designed with redundancy and fault detection. This means having multiple channels or components capable of performing safety functions. If one component fails, the system should detect the failure and continue to provide safety coverage.

- Manual Reset and Monitoring: OSHA guidelines emphasize the need for systems that require a manual reset after a safety function is triggered. This ensures that machine operators are aware of a fault or hazard condition and must intervene to restart operations. Continuous monitoring of the circuit also helps detect any malfunctions or failures in real-time.

- Safety Relays and Control Devices: The use of safety relays and reliable control devices, such as emergency stop buttons and light curtains, is crucial to comply with OSHA standards. These devices must be designed to withstand rigorous conditions and consistently perform their safety functions when needed.

- Documentation and Maintenance: OSHA requires thorough documentation of all safety systems, including wiring diagrams, risk assessments, and maintenance logs. Regular maintenance checks are essential to ensure that safety circuits continue to operate as designed, especially after modifications to the system.

Compliance with OSHA Machine Guarding Standard

To comply with OSHA’s machine guarding standard, employers must ensure that all machinery is equipped with proper guarding, including control reliable safety circuits where necessary. Properly implemented, these circuits protect operators from hazards, such as moving parts, electrical shocks, and accidental startups. OSHA compliance involves:

- Installing proper safeguards: This includes physical barriers, presence-sensing devices, or safety interlocks that prevent access to hazardous areas.

- Regular inspections: Periodic inspections of machine guards and safety circuits are essential to ensure ongoing protection.

- Training workers: Employees should be trained on how to use emergency stop mechanisms, understand safety features, and report any issues with machine guarding or control systems.

Conclusion

Implementing a control reliable safety circuit is a critical aspect of meeting OSHA safety requirements, particularly in environments where heavy machinery is in use. By focusing on redundancy, fault detection, and regular maintenance, employers can ensure the safety of their workers and reduce the risk of workplace accidents. Compliance with OSHA standards not only safeguards employees but also enhances productivity by minimizing downtime caused by machine malfunctions or accidents.

No comments yet