Warehouse Health Risks build up when a warehouse is designed for speed but not for the human body. Order pickers may walk long distances per shift, bend to the first layer of pallets, reach overhead for fast movers stored too high, and pinch-grip small packages while scanning at a machine-paced rate.

Over time, those patterns can turn into fatigue, soreness, and lost capacity—especially in peak season when overtime becomes “normal.”

- Warehouse Health Risks: what makes repetitive picking so hard on the body

- Warehouse Health Risks: early warning signs supervisors should act on

- Warehouse Health Risks from fatigue: why overtime and shift design matter

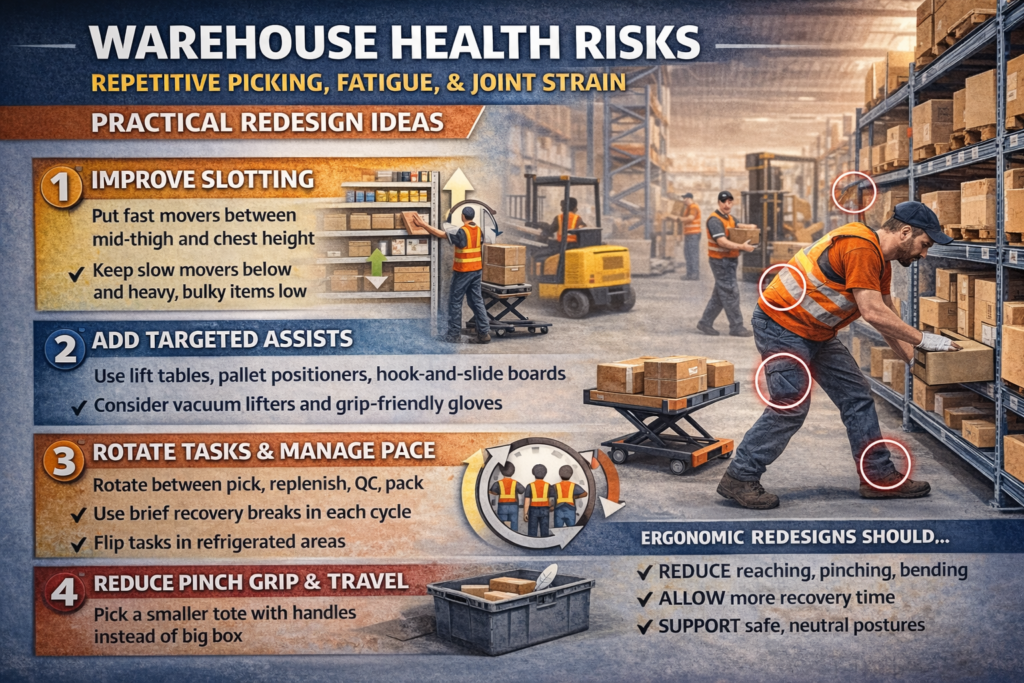

- Warehouse Health Risks: practical redesign idea 1 — slotting and the “golden zone”

- Warehouse Health Risks: practical redesign idea 2 — reduce force with targeted assists

- Warehouse Health Risks: practical redesign idea 3 — pace, rotation, and micro-recovery

- Warehouse Health Risks: practical redesign idea 4 — protect hands and reduce pinch grip

- Warehouse Health Risks: Ontario-friendly resources and training integration

- How to know your redesign is working

Warehouse Health Risks: what makes repetitive picking so hard on the body

Repetitive picking isn’t one movement; it’s a cycle repeated thousands of times: reach, grasp, move, place, and scan. CCOHS explains that repetition becomes especially hazardous when the same joints and muscle groups are used too often, too quickly, and for too long, and that faster pace reduces recovery time between cycles.

NIOSH also summarizes strong links between musculoskeletal problems and combined risk factors such as force + repetition and force + posture—exactly what shows up when pick rates are high and product locations force bending, reaching, and twisting.

In practical terms, the body starts to compensate as fatigue grows: shoulders hike up, wrists bend more, and the back rounds deeper on low picks. That compensation is why “the last two hours” of a long shift often feel like a different job than the first two hours. If your warehouse relies on constant peak pace, the design is quietly borrowing from workers’ joints and recovery.

Warehouse Health Risks: early warning signs supervisors should act on

The early signals are usually performance-adjacent: more mis-scans, more short picks, more dropped items, and more workers “shaking out” their hands between picks.

Workers may mention burning forearms, sore shoulders, or knees that ache after low pallet picks. These are not just comfort issues; they are risk indicators that the cycle time, posture, or force demands are too high.

A simple habit helps: ask for a quick end-of-shift discomfort check (shoulders, back, wrists, knees, feet) and compare it to where the person worked that day.

Pair that with a brief walkthrough using a checklist. NIOSH specifically recommends walking through work areas, observing several workers on the same task, and interviewing workers and supervisors who know the job well.

Warehouse Health Risks from fatigue: why overtime and shift design matter

Fatigue is not only “feeling tired.” The UK HSE defines fatigue as a decline in mental and/or physical performance arising from excessive working time or poorly designed shifts, and notes it is closely tied to machine-paced, complex, or monotonous workload.

In a warehouse, that decline shows up as slower reactions around equipment, reduced attention to pedestrians and pinch points, and a bigger tendency to use risky postures late in the shift.

If you want a fast win, treat fatigue like a hazard with limits. Set rules for maximum consecutive long shifts, minimum recovery time between shifts, and a plan for overtime surges. HSE also points out that the incidence of accidents and injuries is higher on night shifts, after successive shifts, when shifts are long, and when breaks are inadequate.

A fatigue policy only works if supervisors are supported with staffing options and are not forced to “solve” volume by stretching the same people every day.

Warehouse Health Risks: practical redesign idea 1 — slotting and the “golden zone”

Slotting is often your highest return change because it reduces bending and reaching without buying new equipment. Put fast movers where hands naturally work: between mid-thigh and chest.

OSHA’s warehousing guidance recommends keeping high-volume items near standing elbow height and limiting consolidated orders to shoulder height to reduce awkward postures. This one change can remove hundreds of overhead reaches and deep bends per person per day.

Don’t stop at height. Reduce long reaches by bringing pick faces closer, widening aisles where tight turns force twisting, and keeping pallet build areas accessible from multiple sides.

OSHA also recommends raising pallets used for order consolidation to reduce bending on the first layer and placing heavier cases on the bottom of an order. Those details matter because the “first layer” is where the deepest bends happen, and deep bends repeated all day are a classic low-back strain pathway.

Warehouse Health Risks: practical redesign idea 2 — reduce force with targeted assists

Not every warehouse can automate, but most warehouses can add targeted assists where force is highest. Lift tables, pallet positioners, vacuum lifters, and simple slide boards reduce back and shoulder load during pallet building.

Better cart design—larger wheels, maintained bearings, and consistent floor maintenance—reduces push/pull forces that quietly overload shoulders and elbows over a shift.

OSHA also notes that cold environments can increase gripping force and pressure during handling, which can worsen other musculoskeletal risk factors. If you operate in refrigerated zones, rotate tasks out of cold areas, provide warm-up time, and ensure gloves still allow safe grip without requiring a “death squeeze” on cases.

Warehouse Health Risks: practical redesign idea 3 — pace, rotation, and micro-recovery

Even with perfect slotting, high-volume work can overwhelm recovery if the pace is relentless.

Build job rotation that truly changes body regions (for example: pick → pack → replenish → quality check), instead of rotating between two equally wrist-dominant tasks. OSHA explicitly recommends job rotation and work/rest cycles to provide whole-body and local muscle fatigue recovery.

Micro-breaks work best when they are short, predictable, and supervisor-supported. A 60–90 second reset every 25–30 minutes can reduce cumulative fatigue without “killing productivity,” especially if it’s paired with small process improvements like fewer steps and fewer re-handles. The key is consistency: recovery doesn’t work if workers only rest when the line stops.

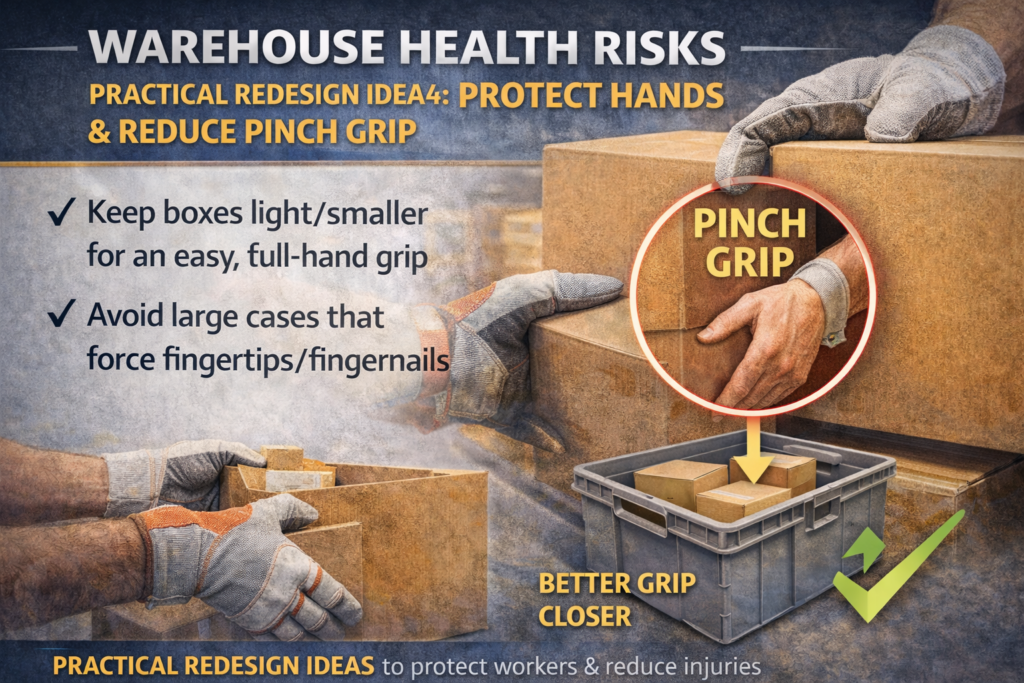

Warehouse Health Risks: practical redesign idea 4 — protect hands and reduce pinch grip

Repetitive scanning and small-item picking often drive wrist and forearm symptoms. Reduce pinch grip by improving container design (better handles, smaller case sizes, or totes that don’t require fingertip lifting). Keep heavier items close to the body and avoid forcing one-handed lifts with awkward packages.

OSHA’s warehousing tips include ideas like raising pallets so lifts occur between knees and mid-chest and keeping item weights low when a pinch grip is used.

You don’t have to copy exact numbers to benefit from the principle: the more awkward the grip, the lower the safe weight and the shorter the safe exposure time.

Warehouse Health Risks: Ontario-friendly resources and training integration

If you’re operating in Ontario, WSPS notes that order picking can cause muscle and joint injuries from repeatedly or forcefully reaching for and lifting product, using scanners, and similar actions.

That makes WSPS a useful external reference when you’re explaining to workers why changes like slotting, rotation, and lift assists are safety controls—not “making the job easier.”

To keep the program consistent across new hires and peak-season temps, tie your expectations into onboarding and refreshers. If you already use OHSE.ca for learning and verification, embed a short ergonomics/fatigue module into your training flow so reporting and safe work methods become standard practice across shifts. You can also point supervisors and workers to your internal certification pathway at OHSE.ca/get-certification.

For toolbox talks and supervisor coaching, these external resources are strong references: NIOSH ergonomics risk factors, CCOHS WMSD risk factors, OSHA warehousing hazards and solutions, HSE fatigue guidance, and WSPS warehouse order picking safety tips.

How to know your redesign is working

Warehouse Health Risks drop when workers spend more time in neutral postures, use less hand force, and get real recovery time built into the shift. Track a few simple indicators: discomfort reports by area, overtime hours, pick errors, and near misses around pedestrian-vehicle interfaces.

When the redesign is right, you’ll usually see fewer complaints, fewer errors late in shift, and steadier retention through peak season—without sacrificing output. Warehouse Health Risks

No comments yet