Compressed Gas Cylinders : Safe Use of Compressed Gas Cylinders in the Workplace is critical for maintaining a hazard-free environment in manufacturing, laboratories, welding, construction, healthcare, and countless other industries.

These cylinders may look stable, but if mishandled, they can become explosive missiles or release toxic gases, posing serious risks to life and property.

Employers must ensure proper training, handling, storage, and inspection procedures are followed consistently to minimize accidents and comply with occupational safety regulations.

- Why Compressed Gas Cylinder Safety Matters

- Key Safety Tips for the Use of Compressed Gas Cylinders

- Required Personal Protective Equipment (PPE)

- Safe Cylinder Storage: Do's and Don'ts

- What to Do in Case of a Gas Leak or Emergency

- Employee Training and Employer Responsibilities

- Final Thoughts on Safe Use of Compressed Gas Cylinders in the Workplace

Why Compressed Gas Cylinder Safety Matters

Compressed gases are stored under high pressure, making even a small leak potentially dangerous. Cylinders can contain flammable gases (like acetylene or propane), toxic gases (like ammonia or chlorine), or oxidizers (like oxygen or nitrous oxide). Improper use may result in:

- Fires or explosions

- Oxygen enrichment or asphyxiation

- Equipment damage

- Serious injury or death

According to CCOHS, improper cylinder handling is a leading cause of industrial gas-related accidents in Canada. Adherence to safety guidelines is not optional—it’s essential.

Common Types of Compressed Gas Cylinders at Work

| Gas Type | Examples | Hazards |

|---|---|---|

| Flammable Gases | Acetylene, Propane, Hydrogen | Fire, explosion |

| Oxidizers | Oxygen, Nitrous Oxide | Intensifies combustion |

| Inert Gases | Nitrogen, Argon, Helium | Asphyxiation in confined spaces |

| Toxic Gases | Ammonia, Chlorine | Poisoning, chemical burns |

| Corrosive Gases | Hydrogen Chloride, Sulfur Dioxide | Tissue damage, container corrosion |

Understanding these categories helps workers choose the correct PPE and storage conditions for each cylinder.

Key Safety Tips for the Use of Compressed Gas Cylinders

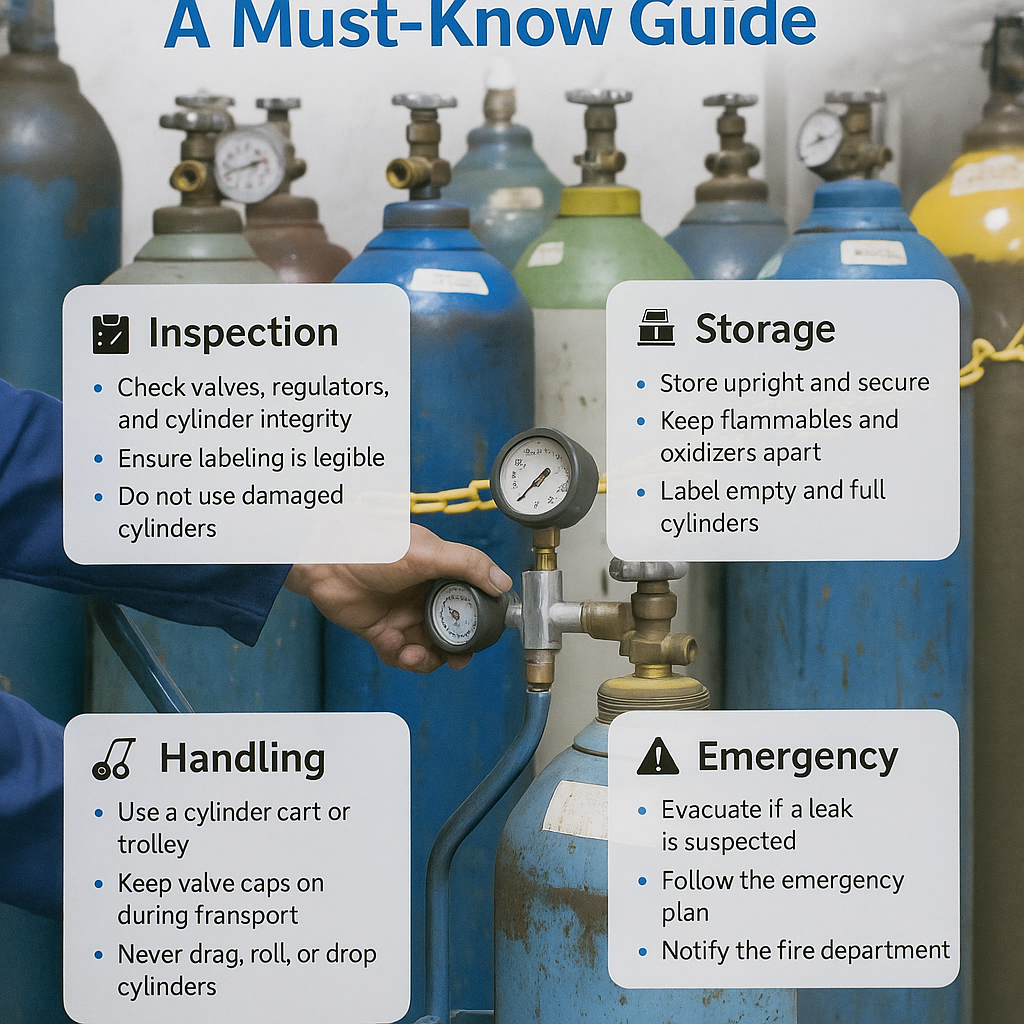

1. Always Inspect Before Use

- Check valves, regulators, and cylinder integrity.

- Ensure labeling is legible and corresponds to contents.

- Never use damaged or corroded cylinders.

2. Use Proper Storage Techniques

- Store cylinders upright and secure them with chains or brackets.

- Keep flammable gases at least 6 meters from oxidizers.

- Store in well-ventilated, dry, and fire-resistant areas.

3. Labeling and Identification

- Never rely on color alone—read the manufacturer’s label.

- Clearly label empty and full cylinders.

- Use signs to designate storage and usage areas.

4. Proper Handling and Transportation

- Use a cylinder cart or trolley with safety straps.

- Keep valve caps on during transport.

- Never drag, roll, or drop cylinders.

5. Valve and Regulator Safety

- Open valves slowly while standing to the side.

- Do not attempt to repair faulty valves.

- Use regulators designed for the specific gas type.

Required Personal Protective Equipment (PPE)

Workers must wear appropriate PPE when handling or using gas cylinders, including:

- Safety goggles or face shields

- Flame-resistant gloves

- Steel-toe safety boots

- Aprons or lab coats (if applicable)

For hazardous or toxic gases, respiratory protection may be required. Refer to the company’s Respiratory Protection Program for guidelines.

Safe Cylinder Storage: Do’s and Don’ts

| Do | Don’t |

|---|---|

| Store upright and secure cylinders | Lay cylinders on the floor |

| Separate incompatible gases | Store oxidizers with flammable gases |

| Use proper signage and warning labels | Store in unmarked or unauthorized areas |

| Ensure ventilation and leak detection | Store near heat sources or direct sunlight |

What to Do in Case of a Gas Leak or Emergency

- Evacuate the area immediately.

- Activate the emergency shutoff system if available.

- Notify the fire department and the workplace safety officer.

- Use appropriate extinguishers only if trained and it’s safe to do so.

Emergency planning should include incident response drills and visible signage for safety showers, eye washes, and exits.

Employee Training and Employer Responsibilities

Under OHSA and CCOHS regulations, employers must ensure:

- Workers are trained in cylinder identification, handling, and emergency procedures.

- Cylinders are inspected regularly.

- PPE is available and properly used.

- Workers understand the risks associated with gases used on-site.

Employers should also promote a safety culture where staff feel empowered to report concerns. For best practices, see our guide on Safety Culture and Reporting.

Final Thoughts on Safe Use of Compressed Gas Cylinders in the Workplace

Safe Use of Compressed Gas Cylinders in the Workplace isn’t just about ticking compliance boxes—it’s about protecting lives. With the right training, procedures, and oversight, employers can mitigate the risks associated with high-pressure gases and foster a safer working environment for all.

By investing in proper storage, PPE, labeling, and emergency preparedness, companies not only meet regulatory requirements but also build trust and safety among their workforce.

No comments yet