Understanding Color-Coded Emergency Codes in Industrial Workplaces is essential to building a fast, efficient, and life-saving emergency response system.

From “Code Red” signaling fire to “Code Black” warning of a bomb threat, these color-based alerts act as a universal language for danger across many industrial environments.

Color-coded systems reduce confusion, ensure quick recognition, and allow for rapid action—even when verbal communication isn’t possible.

Whether you’re a plant worker, supervisor, or OHSE manager, knowing these codes is a fundamental part of workplace safety.

- 🧱 Why Use Color-Coded Emergency Codes?

- 📋 Common Color-Coded Emergency Codes in Industrial Workplaces

- 🔥 Example: Code Red in a Manufacturing Facility

- 📦 Application by Industry

- 📢 How Color Codes Are Communicated

- 🧠 Benefits of Color Coding in Safety

- 🛠 Implementation Tips for Employers

- 📘 Real Example: WHMIS & GHS Color Labeling

- 📚 Related Emergency Signal Words

🧱 Why Use Color-Coded Emergency Codes?

In high-risk industrial settings—like factories, chemical plants, and warehouses—every second counts. Color-coded emergency systems provide:

- Quick recognition of hazard type

- Non-verbal communication in noisy or chaotic environments

- Universal alerts that reduce language barriers

- Standardization across departments

Most color codes are developed internally but are often modeled after healthcare and public emergency systems, especially where large teams operate in complex conditions.

📋 Common Color-Coded Emergency Codes in Industrial Workplaces

Let’s break down the most widely used color codes in industrial environments. Keep in mind, organizations may customize these slightly depending on operations, risk levels, or regulations.

| Color Code | Emergency Type | Action Triggered |

|---|---|---|

| Code Red | Fire | Sound fire alarms, evacuate, use extinguishers |

| Code Blue | Medical Emergency | Dispatch first aid or emergency response team |

| Code Black | Bomb Threat | Initiate bomb threat protocol, notify law enforcement |

| Code Yellow | Hazardous Spill | Contain, evacuate, activate HazMat protocol |

| Code Orange | Evacuation | Full site evacuation or area-specific egress |

| Code Green | All Clear | Emergency resolved, return to normal operations |

| Code White | Workplace Violence | Lockdown or security intervention |

| Code Grey | Infrastructure Failure | Report to emergency leads, standby for further orders |

| Code Purple | Missing Person | Initiate search protocol or restricted access |

🔥 Example: Code Red in a Manufacturing Facility

Imagine a large automotive plant with hundreds of workers. A fire breaks out in the welding zone. An employee sees smoke and activates a Code Red through the emergency panel. Instantly:

- Fire alarms ring throughout the building

- Staff evacuate following red exit signs

- Fire wardens grab extinguishers and PPE

- Local fire services are notified

The color red universally signals danger and fire, making the code instantly recognizable even for new workers or non-native speakers.

📦 Application by Industry

🏭 Manufacturing & Heavy Industry

- Code Red and Code Yellow are most common.

- Codes often integrated with flashing lights and audible sirens.

- Evacuation plans color-match routes and zones.

🧪 Chemical & Lab Environments

- Use Code Yellow or HazMat Alert for spills.

- Often involve Code Blue due to exposure risks.

🏥 Healthcare & Pharmaceutical Plants

- Borrow heavily from hospital protocols (Code Blue, White, Black).

- Used in conjunction with patient evacuation or containment.

🏗️ Construction Sites

- Code systems are simplified; rely heavily on Code Red, Man Down, and Evacuate Now.

📢 How Color Codes Are Communicated

Color-coded alerts can be transmitted in various ways:

- Public Address (PA) Systems:

“Attention all personnel: Code Yellow in Zone 3.” - Visual Alarms and Lights:

- Red strobe = fire

- Blue strobe = medical

- Amber strobe = chemical or machinery hazard

- Mobile Alerts / Wearables:

- Safety apps can push color-coded alerts directly to staff devices.

- Posters and Signage:

Posted in common areas and near emergency stations.

🧠 Benefits of Color Coding in Safety

- Faster decision-making during emergencies

- Reduces panic by providing clear direction

- Improves training outcomes through visual reinforcement

- Standardizes emergency preparedness across departments

Even when words fail, colors convey urgency, action, and intent.

🛠 Implementation Tips for Employers

- Customize to Your Risk Profile:

Codes should match the unique hazards of your worksite. - Train Regularly:

Conduct drills at least twice a year covering all codes. - Post Visual Guides:

Include color-coded reference charts in break rooms, locker areas, and control panels. - Integrate with Technology:

Use digital displays, wearable alerts, and connected systems. - Include in ERP & SOPs:

Document color codes in your Emergency Response Plans (ERP) and Standard Operating Procedures (SOPs).

📘 Real Example: WHMIS & GHS Color Labeling

In Canada and globally, WHMIS and GHS use standardized color codes and pictograms for hazardous materials. While not “codes” in the verbal sense, they reinforce the visual communication of hazard severity:

- Red diamond: Flammable, explosive

- Yellow triangle: Caution or warning

- Blue circle: Mandatory PPE

- Black pictograms: Type of hazard (e.g., corrosive, toxic)

Learn more about WHMIS (DoFollow)

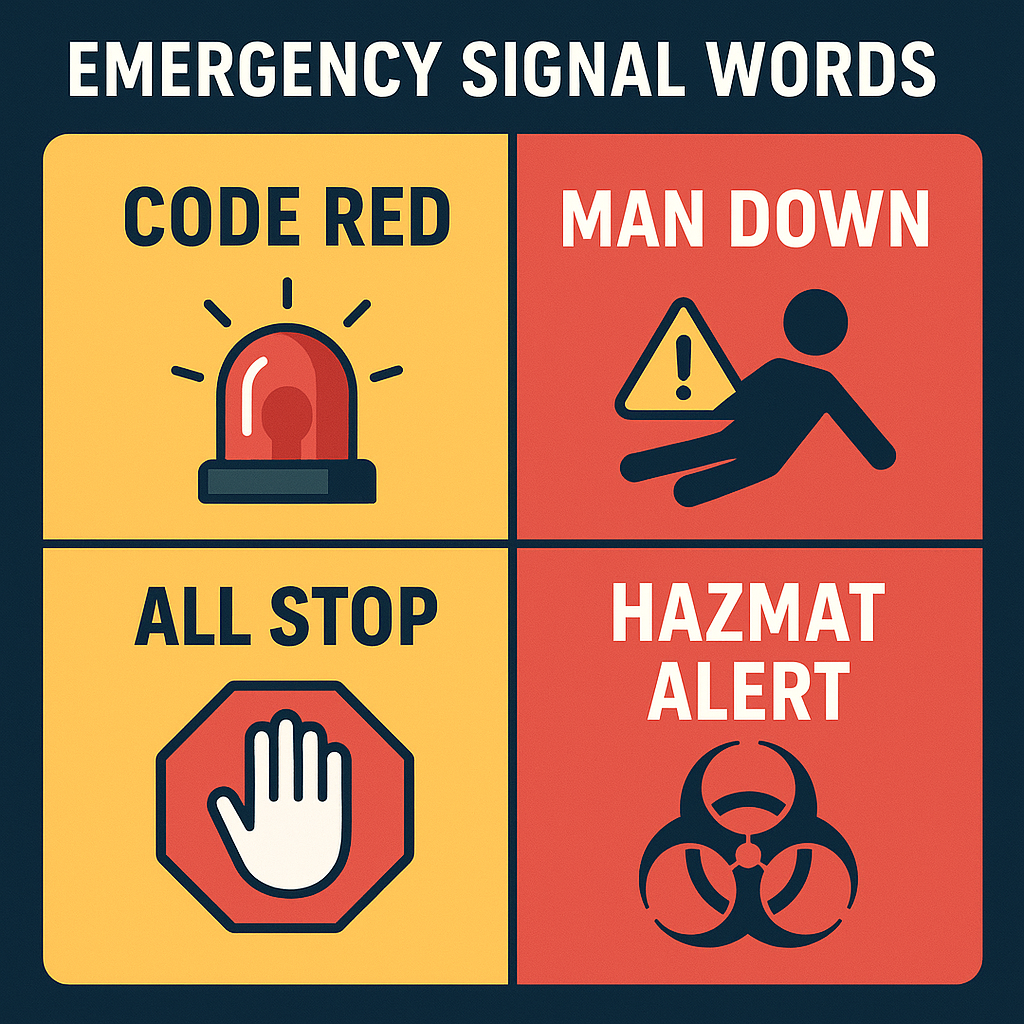

📚 Related Emergency Signal Words

Many color codes are used alongside verbal or symbolic signal words, such as:

- “Evacuate Now”

- “HazMat Alert”

- “All Stop”

- “Man Down”

- “Radio Silence”

For a full guide, read: 10 Emergency Signal Words Every Workplace Should Know

No comments yet