Filler Metal plays a vital role in creating strong, reliable joints across welding, brazing, and soldering operations.

Whether in heavy industrial fabrication or fine electronics work, understanding the characteristics of filler metals, as well as the purpose of fluxes and powders, is key to achieving quality results and safe processes.

This comprehensive guide explores their types, applications, and safety considerations for a wide range of joining methods.

What is Filler Metal?

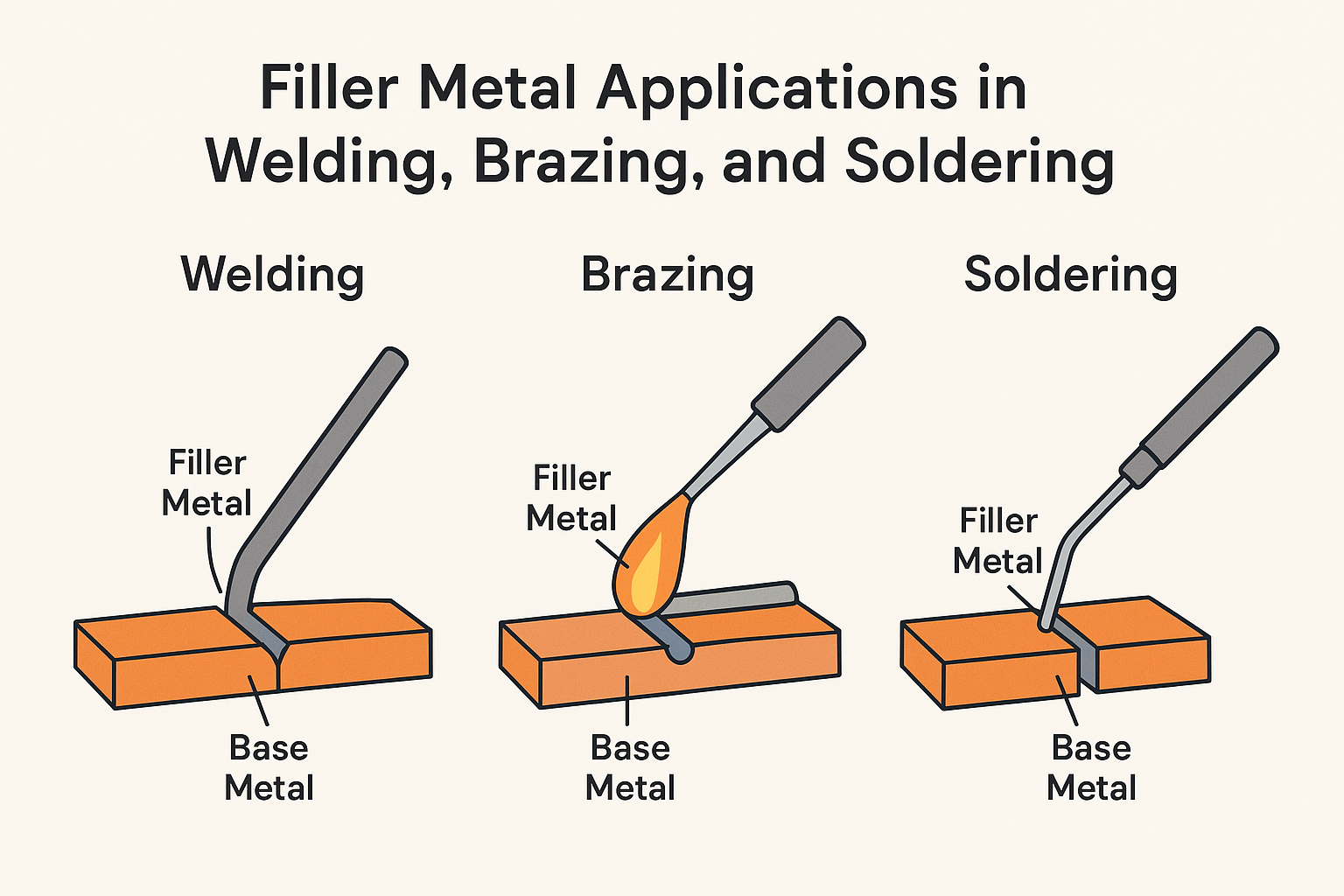

Filler metal is a material added to a joint during welding, brazing, or soldering to help bond two base metals. It melts during the process and fuses with the workpieces, filling the gap and contributing to the strength of the joint.

Filler metals may be used with or without a flux and may appear in the form of rods, wires, pastes, or powders depending on the process.

Types of Filler Metal by Joining Process

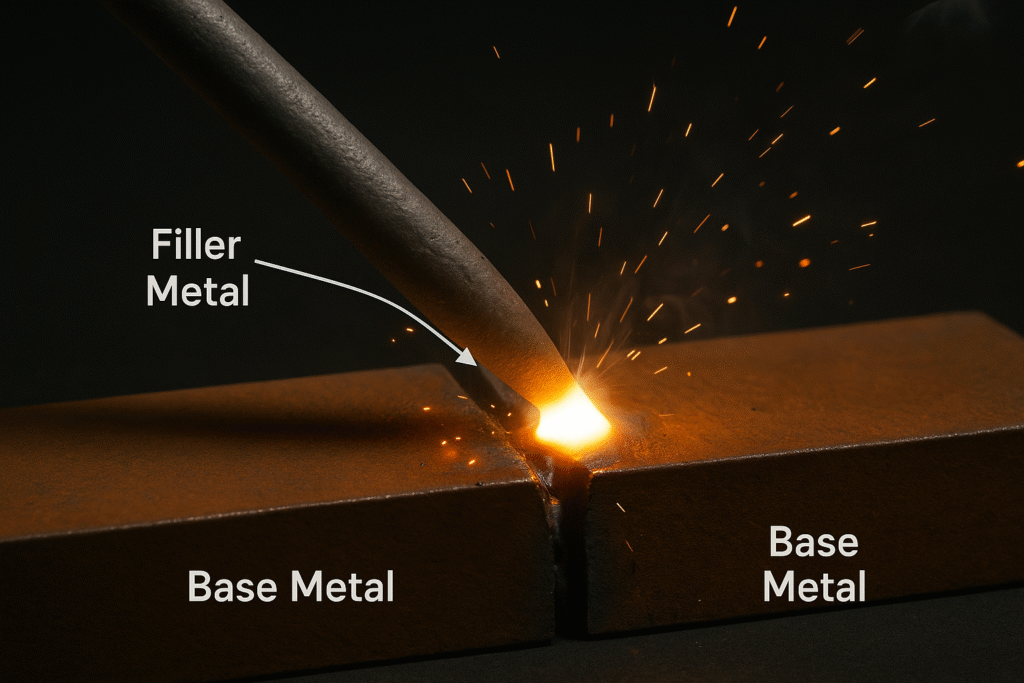

Filler Metal in Welding

Welding involves melting the base metals and adding a compatible filler metal. Common welding filler metals include:

- Mild steel (ER70S-6) – used in MIG welding.

- Stainless steel (308L, 309L rods) – for TIG and stick welding.

- Aluminum (4045, 5356) – often used in aerospace and automotive welding.

Each of these comes with designated AWS (American Welding Society) classifications. For example, ER70S-6 is widely used for its high ductility and good wetting action.

Filler Metal in Brazing

In brazing, the filler metal melts above 450°C (840°F) but below the melting point of the base metals. Brazing filler materials often include:

- Silver alloys – excellent flow and low corrosion.

- Copper-phosphorus alloys – used for HVAC tubing.

- Aluminum-silicon alloys – used in automotive manufacturing.

Silver-based brazing fillers are popular due to their ease of use and ability to join dissimilar metals.

Filler Metal in Soldering

Soldering filler metals melt below 450°C and are typically used in electronics and plumbing. Common types include:

- Lead-free solders (SnAgCu) – environmentally friendly and RoHS compliant.

- Tin-lead solder (Sn63Pb37) – excellent electrical properties but increasingly phased out due to toxicity.

What are Fluxes and Why Are They Important?

Flux is a chemical cleaning agent that removes oxides and prevents their formation during heating. This is essential for ensuring the molten filler metal properly bonds to the base metals.

Without flux, oxidation can prevent adhesion and weaken the joint.

Types of Flux by Process

| Process | Type of Flux | Function |

|---|---|---|

| Welding | In flux-cored wires, shielding gas | Removes impurities and protects arc |

| Brazing | Borax-based flux | Promotes wetting, prevents oxidation |

| Soldering | Rosin or water-soluble | Cleans and prepares metal surfaces |

In flux-cored arc welding (FCAW), the flux is built into the wire, releasing shielding gas and slag that protect the weld pool. In soldering, the flux may come as a paste, liquid, or part of the wire core.

Metal Powders in Joining Processes

Metal powders serve as both filler and coating agents. They are widely used in:

- Powder brazing – for producing strong, thin joints in high-volume manufacturing.

- Thermal spraying – applying metal coatings for corrosion or wear resistance.

- Additive manufacturing – building components layer by layer using metal powders.

The powder is typically pre-mixed with flux and applied as a paste or preform, then melted during the heating cycle.

How to Choose the Right Filler Metal and Flux

Selecting the proper filler metal and flux depends on several factors:

- Base Metal Compatibility: Match filler composition to base metals for proper bonding and corrosion resistance.

- Application Temperature: Ensure the filler melts at a suitable range for the process.

- Joint Strength and Ductility: Consider mechanical requirements of the finished joint.

- Safety and Health Regulations: Some materials (like lead or cadmium) have strict usage limitations.

Refer to manufacturer specifications and standards from organizations like the AWS and ISO for proper selection guidelines.

Safety Considerations When Working with Filler Metal and Flux

Ventilation and Fume Control

Flux and filler materials often release hazardous fumes when heated. For example, rosin-based fluxes can cause respiratory irritation, and some brazing fillers may contain cadmium, which is toxic.

- Use local exhaust ventilation (LEV) systems at workstations.

- Wear approved respirators, especially in confined spaces.

- Use PPE like gloves, safety glasses, and welding aprons.

Storage and Handling

- Store filler rods and powders in dry, clean areas to avoid contamination.

- Label materials clearly, especially if using hazardous fluxes or metals.

- Avoid direct contact with flux powders—many are corrosive or skin irritants.

For more on safe handling practices, visit Canadian Centre for Occupational Health and Safety (CCOHS) or OHSE.ca.

Innovations in Filler Metal and Flux Technology

Recent developments in filler metal technology aim to improve efficiency, joint quality, and environmental safety:

- Nanoparticle fluxes for faster soldering at lower temperatures.

- Low-silver and lead-free alloys to meet health regulations.

- Pre-formed brazing rings and pastes for automated processes.

- Smart fluxes that change color when the optimal temperature is reached.

These advances reduce costs, improve reliability, and contribute to sustainable manufacturing.

Real-World Applications of Filler Metal

- Aerospace: TIG welding with Inconel filler in high-performance turbines.

- Electronics: Fine soldering using SnAgCu on PCBs.

- HVAC: Copper brazing rods in refrigeration lines.

- Automotive: Robotic MIG welding with flux-cored wires for body panels.

The versatility of filler metals makes them indispensable across industries.

Mastering Filler Metal Use for Safe, Strong Joints

Filler metal is the backbone of quality joints in welding, brazing, and soldering operations. From choosing the right alloy to ensuring the correct flux and powder are applied safely, knowledge is critical for achieving durability, efficiency, and safety in metal joining.

Whether you’re a welder, technician, or safety officer, understanding the role of filler metal enhances both performance and protection.

Filler Metal isn’t just a consumable—it’s a cornerstone of metalworking excellence.

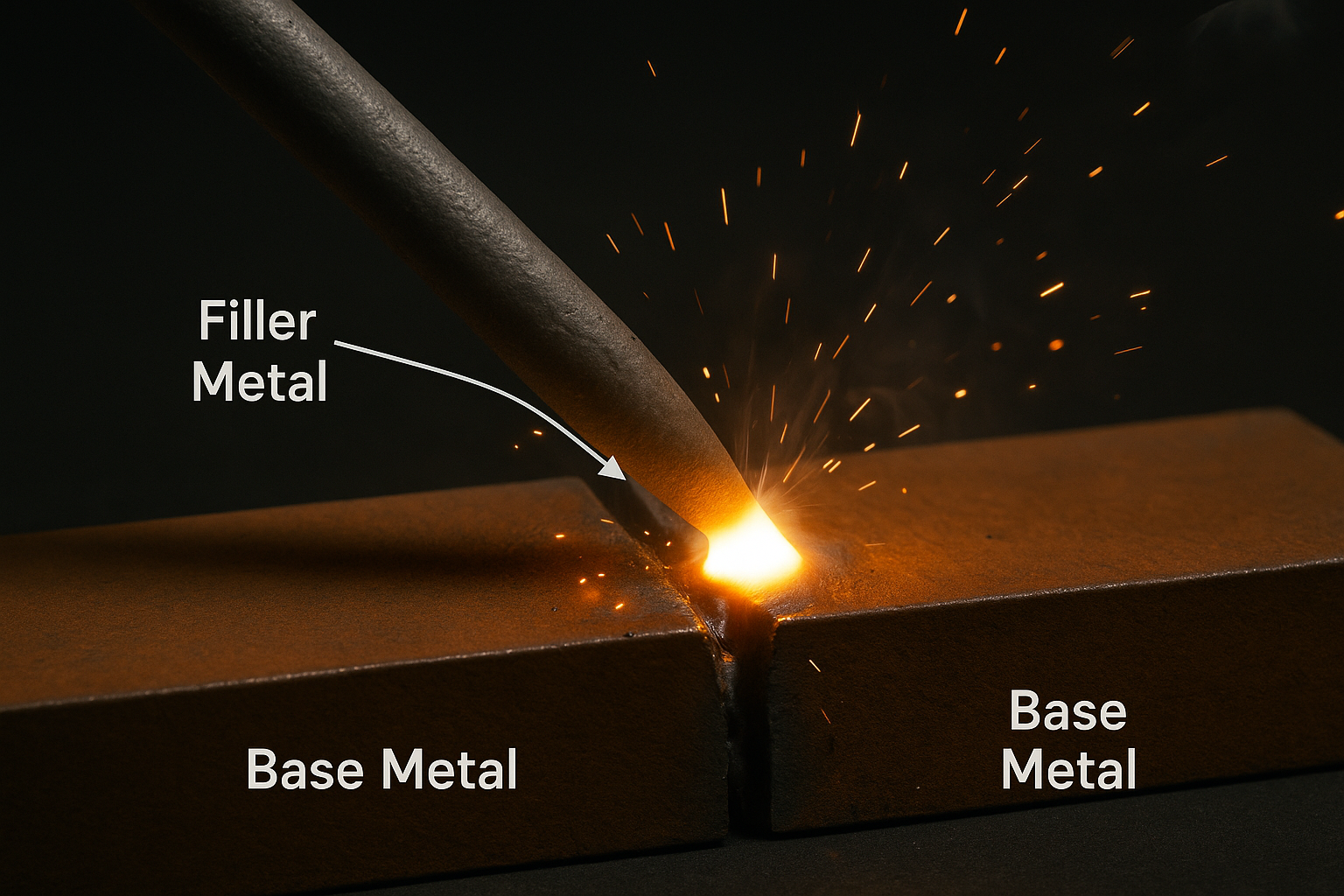

The difference between filler metal and weld metal lies in their roles and definitions during the welding process:

Filler Metal

- Definition: Filler metal is the material added to the weld joint to help form the weld. It is usually in the form of a wire, rod, or electrode.

- Function: It fills the gap between the base metals being joined.

- Examples: Welding rods in SMAW (stick welding), wire in MIG welding, or rods in TIG welding.

- Not always present: Some welding methods (like autogenous welding) don’t use filler metal at all.

Weld Metal

- Definition: Weld metal is the portion of the metal that has melted and solidified to form the final weld. It includes both the filler metal and melted base metal in the fusion zone.

- Function: It is the actual fused material that holds the two base metals together after cooling.

- Always present: Even without filler metal, there will always be weld metal where fusion occurs.

| Term | Description | Role in Welding |

|---|---|---|

| Filler Metal | Added material used to bridge and fuse base metals | Enhances joint strength and fill |

| Weld Metal | Final solidified metal in the weld, including filler | Structural part of the final weld |

In Simple Terms:

- Filler metal is like the brick mortar you add while building.

- Weld metal is the final, hardened structure made from both the bricks (base metals) and mortar (filler + fused base).

Key Factors to Consider When Selecting a Filler Metal

Selecting a filler metal is a critical step in achieving strong, reliable, and defect-free welds. At the beginning of this article, we’ll examine the essential considerations that should guide your selection—focusing on material compatibility, welding process, service conditions, and regulatory standards. The right filler metal not only ensures the structural integrity of the joint but also optimizes performance, durability, and safety.

1. Base Metal Compatibility

The filler metal must match or be compatible with the base materials being joined. Using a filler with a vastly different chemical or mechanical profile can lead to weld cracking, corrosion, or weak joints.

Considerations include:

- Similar composition (e.g., stainless-to-stainless or aluminum-to-aluminum)

- Metallurgical compatibility for dissimilar joints

- Dilution effect between base and filler

💡 Tip: For carbon steel, a filler with matching carbon content is ideal. For stainless steel, match both alloy type and corrosion resistance.

2. Welding Process Type

Different welding processes require specific forms and types of filler metal.

| Process | Filler Form | Example |

|---|---|---|

| SMAW (Stick) | Coated electrodes | E7018 |

| GMAW (MIG) | Wire spool | ER70S-6 |

| GTAW (TIG) | Bare rod | ER308L |

| FCAW | Flux-cored wire | E71T-1C |

Choose a filler metal formulated for your selected welding method to ensure smooth arc stability, deposition rate, and penetration.

3. Mechanical Properties

The filler metal must match the required mechanical properties of the welded structure. This includes:

- Tensile strength

- Yield strength

- Ductility

- Toughness (especially at low temperatures)

Refer to AWS filler metal classifications (e.g., E7018 = 70 ksi tensile strength) for guidance. If the filler metal underperforms, the entire joint may fail under stress.

4. Service Conditions

Consider the environment where the final product will be used. Factors such as temperature extremes, corrosive environments, pressure, or fatigue play a huge role.

Examples:

- Marine environments: Use corrosion-resistant fillers like ER316L.

- Cryogenic applications: Choose fillers tested for low-temperature impact toughness.

- Pressure vessels: Comply with ASME Section IX filler metal approvals.

5. Welding Position and Technique

Some filler metals are formulated for flat positions only, while others can be used in all positions (flat, horizontal, vertical, overhead).

Check AWS designations:

- 1 = all positions (e.g., E7018-1)

- 2 = flat and horizontal only

Welding out of position with the wrong filler can result in slag inclusions, undercuts, and poor fusion.

6. Code and Regulatory Compliance

Ensure the filler metal meets relevant industry codes or client specifications.

- AWS (American Welding Society)

- ASME Boiler and Pressure Vessel Code

- ISO/EN classifications

- Military or aerospace standards

Certificates of conformity and batch traceability may be required for high-spec projects.

7. Shielding Gas Compatibility

In MIG or TIG welding, the shielding gas must match the filler metal to avoid porosity, contamination, or poor bead appearance.

- Mild steel: Argon + CO₂

- Stainless steel: Tri-mix (He/Ar/CO₂) or pure argon

- Aluminum: 100% argon

Your filler metal spec sheet typically lists compatible gases.

8. Post-Weld Requirements

If the welded part will undergo heat treatment, machining, or painting, choose a filler metal that supports these operations.

- Low-hydrogen electrodes for parts that require stress relief

- Smooth-running wire for cosmetic welds

- Low-silicon fillers for paintability

9. Cost and Availability

While performance is critical, consider the cost-effectiveness and supply availability of your chosen filler.

- Is it available locally?

- Is it priced within project budget?

- Can you buy in required quantities?

For large-scale projects, consistency of supply is crucial to avoid production delays.

No comments yet