Fire prevention in the workplace is an essential aspect of Occupational Health and Safety (OHSE).

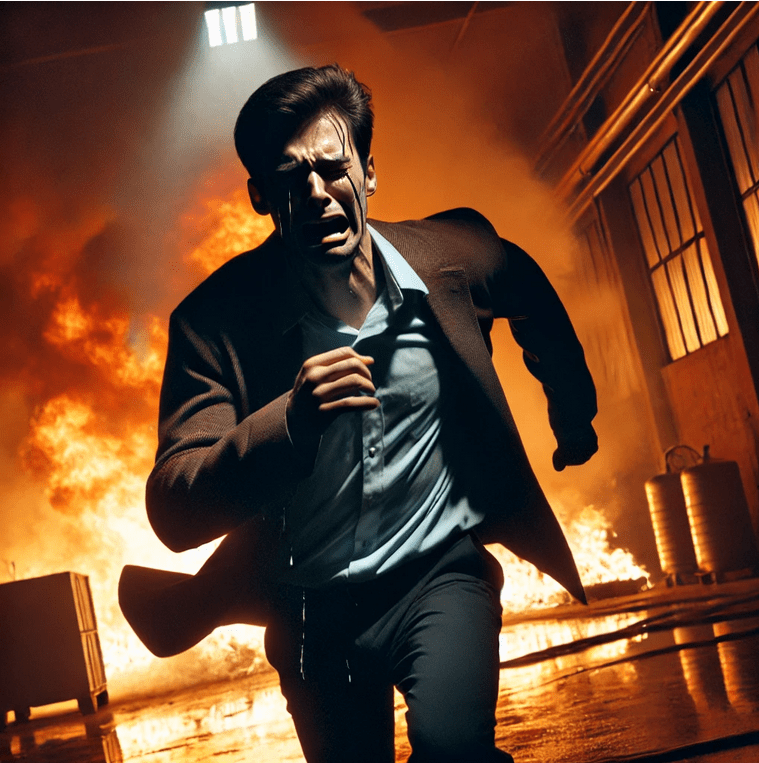

Fires can cause catastrophic damage, including injury, loss of life, destruction of property, and interruptions to business operations. To ensure a safe working environment, companies must adopt comprehensive fire prevention strategies that align with OHSE compliance requirements.

This article outlines the key strategies for fire prevention in the workplace, helping organizations minimize fire hazards, meet regulatory standards, and protect both employees and assets.

- 1. Understanding the Importance of Fire Prevention

- 2. Conducting a Fire Risk Assessment

- 3. Developing a Fire Prevention Plan

- 4. Employee Fire Safety Training

- 5. Proper Storage and Handling of Flammable Materials

- 6. Regular Maintenance of Fire Safety Systems

- 7. Good Housekeeping Practices

- 8. Electrical Safety Measures

- 9. Implementing Fire Suppression Systems

1. Understanding the Importance of Fire Prevention

Workplace fires can arise from a variety of causes, including electrical faults, combustible materials, human error, and machinery malfunctions. The consequences of fires are not only devastating in terms of loss of life and injury but also costly due to downtime, legal liabilities, and damage to business reputation.

OHSE regulations, such as the Occupational Safety and Health Administration (OSHA) in the United States and various fire safety laws worldwide, mandate that businesses take appropriate measures to prevent fires. Failing to comply with fire safety regulations can result in legal penalties, increased insurance premiums, and reputational harm.

2. Conducting a Fire Risk Assessment

The first step toward fire prevention is conducting a thorough fire risk assessment. This process involves identifying potential fire hazards, evaluating the likelihood of fire incidents, and determining the necessary control measures to reduce risks.

Steps for Conducting a Fire Risk Assessment:

- Identify Fire Hazards: Pinpoint sources of ignition (e.g., electrical equipment, heat sources) and combustible materials (e.g., chemicals, paper, fabrics).

- Assess Risks to People: Consider who may be at risk, especially vulnerable individuals like disabled employees or those working in isolated areas.

- Evaluate Existing Control Measures: Review current fire prevention systems, such as fire alarms, extinguishers, and sprinkler systems, and assess whether they are adequate.

- Implement Additional Controls: Where necessary, introduce further measures to minimize risks, such as upgrading equipment or improving employee training.

- Review and Update Regularly: Risk assessments should be updated periodically or whenever there are significant changes to the workplace, such as renovations or the introduction of new equipment.

3. Developing a Fire Prevention Plan

A comprehensive fire prevention plan (FPP) is required for businesses to meet OHSE compliance. This document should outline the measures in place to prevent fires and procedures for responding to emergencies.

Key Elements of a Fire Prevention Plan:

- Identification of Fire Hazards: A clear description of fire hazards present in the workplace and their potential impact.

- Preventive Measures: Strategies to prevent ignition and manage combustible materials, such as proper storage of flammable substances, regular maintenance of electrical systems, and ensuring good housekeeping practices.

- Emergency Procedures: Guidelines for responding to a fire, including evacuation plans, fire warden roles, and emergency contacts.

- Maintenance of Fire Safety Equipment: Procedures for ensuring fire extinguishers, alarms, sprinklers, and other safety equipment are regularly inspected and maintained.

- Employee Training: A commitment to providing regular fire safety training to all employees, including the use of firefighting equipment and evacuation procedures.

4. Employee Fire Safety Training

One of the most critical aspects of fire prevention is ensuring that all employees are trained to recognize and mitigate fire risks. Training programs should cover fire safety procedures, proper handling of fire hazards, and how to respond in case of a fire emergency.

Core Components of Fire Safety Training:

- Understanding Fire Hazards: Educating employees about the common causes of workplace fires and how they can avoid them.

- Fire Extinguisher Use: Training employees on the correct use of different types of fire extinguishers (e.g., CO2, water, foam, and powder) and when to use them.

- Evacuation Procedures: Teaching employees the specific steps to take in the event of a fire, such as the locations of exit routes and assembly points.

- Fire Wardens and First Responders: Designating and training individuals to take charge during fire emergencies, guiding evacuations, and liaising with emergency services.

Regular fire drills should be conducted to ensure that all employees are familiar with evacuation procedures and can act quickly and effectively in an emergency.

5. Proper Storage and Handling of Flammable Materials

Workplaces that store or handle flammable or combustible materials must take extra precautions to prevent fires. These materials can include chemicals, solvents, gases, and even paper or fabrics in certain environments.

Best Practices for Handling Flammable Materials:

- Safe Storage: Flammable substances should be stored in approved containers and cabinets, away from ignition sources and in well-ventilated areas.

- Labeling and Signage: Proper labeling of flammable materials and the use of hazard signs should be enforced to ensure everyone is aware of the risks.

- Handling Procedures: Employees should be trained in the correct methods for handling hazardous materials, including transferring, mixing, and disposing of these substances safely.

- Regular Inspections: Conduct regular inspections of storage areas and equipment to ensure compliance with safety standards.

6. Regular Maintenance of Fire Safety Systems

Fire safety systems, such as smoke detectors, fire alarms, and sprinklers, are essential components of workplace fire prevention.

These systems must be regularly inspected and maintained to ensure they function correctly in an emergency.

Key Maintenance Activities:

- Inspecting Fire Extinguishers: Fire extinguishers should be checked monthly to ensure they are fully charged, accessible, and properly maintained.

- Testing Fire Alarms and Detectors: Smoke detectors and fire alarms should be tested regularly to ensure they are operational. Batteries should be replaced annually, and any faulty units should be repaired or replaced immediately.

- Sprinkler Systems: Sprinkler systems should be inspected according to local fire codes, ensuring that they are free from blockages and capable of functioning in the event of a fire.

- Regular Audits: Fire safety audits should be conducted by qualified personnel to evaluate the effectiveness of fire prevention measures and identify areas for improvement.

7. Good Housekeeping Practices

Maintaining a clean and organized workplace is a simple yet effective fire prevention strategy. Good housekeeping reduces the accumulation of combustible materials, ensures clear evacuation routes, and minimizes the risk of fires starting and spreading.

Key Housekeeping Tips for Fire Prevention:

- Dispose of Waste Properly: Ensure that combustible waste, such as paper and packaging, is disposed of regularly and stored away from ignition sources.

- Keep Exits Clear: Exit routes should always be kept free of obstructions to allow for quick and safe evacuation.

- Minimize Clutter: Avoid the buildup of unnecessary materials and equipment, especially in areas with high fire risk, such as near electrical equipment or heat sources.

- Report Hazards: Encourage employees to report fire hazards, such as frayed electrical cords, blocked exits, or improper storage of flammable materials.

8. Electrical Safety Measures

Faulty electrical equipment is a common cause of workplace fires. Proper maintenance and safe use of electrical systems are crucial for preventing electrical fires.

Electrical Safety Best Practices:

- Routine Inspections: Regularly inspect electrical systems, wiring, and equipment for signs of wear or damage. Any issues should be repaired by a qualified electrician.

- Avoid Overloading Circuits: Ensure that electrical outlets and circuits are not overloaded, as this can lead to overheating and fires.

- Use Approved Equipment: Only use electrical equipment that has been approved and tested by recognized safety organizations.

- Unplug Unused Devices: Encourage employees to unplug equipment and devices when they are not in use, especially overnight or during weekends.

9. Implementing Fire Suppression Systems

In addition to fire prevention strategies, workplaces should be equipped with fire suppression systems that can control or extinguish fires before they spread. Sprinkler systems, foam suppression systems, and gas-based suppression systems can be used depending on the specific fire risks present.

Types of Fire Suppression Systems:

- Automatic Sprinklers: These systems activate when heat is detected, releasing water to extinguish the fire.

- Foam Systems: Foam suppression systems are effective for fires involving flammable liquids, such as fuel or chemicals.

- Gas Systems: Gas-based fire suppression systems, such as CO2, are ideal for environments where water could damage equipment, such as data centers or laboratories.

Fire prevention is a crucial component of OHSE compliance, and businesses must take proactive measures to reduce the risk of workplace fires.

By conducting fire risk assessments, developing fire prevention plans, training employees, properly handling flammable materials, and maintaining fire safety systems, organizations can create a safer work environment and ensure the well-being of their employees.

Implementing these fire prevention strategies not only helps to meet legal and regulatory requirements but also fosters a culture of safety within the workplace, minimizing the likelihood of fire-related incidents and ensuring business continuity.

No comments yet