Hand-Arm Vibration is one of those trade hazards that doesn’t always hurt today—but it can quietly damage nerves and blood vessels over time, especially when high-vibration tools become “normal” on the job.

The risk is real across construction, utilities, metal work, shipyards, forestry, maintenance, and any work where grinders, hammer drills, chipping hammers, impact wrenches, or jackhammers show up daily.

NIOSH has warned for decades that vibrating hand tools can cause vibration syndrome (often called vibration white finger) and recommends redesigning jobs/tools and using controls to minimize exposure.

If you’re building OHSE awareness across your crews, you can also reinforce this topic alongside your broader safety training and certification content on OHSE.ca.

- Hand-Arm Vibration and why trades should care now

- Hand-Arm Vibration symptoms you should never ignore

- Hand-Arm Vibration exposure limits and what “A(8)” means in practice

- Hand-Arm Vibration tool selection that actually reduces risk

- Hand-Arm Vibration “limits” depend on time, grip, cold, and maintenance

- Hand-Arm Vibration prevention plan using the hierarchy of controls

- A supervisor-ready Hand-Arm Vibration checklist for job sites

- When to escalate: early reporting protects careers

Hand-Arm Vibration and why trades should care now

Hand-Arm Vibration (HAV) is vibration transmitted from a tool or process into the hands and arms. Over time, repeated exposure can contribute to hand-arm vibration syndrome (HAVS), which involves damage to blood vessels, nerves, muscles, joints, and connective tissue.

CCOHS notes that these conditions often progress slowly, starting with pain and sensory changes, and can worsen with continued exposure—especially in cold conditions.

What makes HAV tricky in trades is that it stacks up. You might use several tools in one shift (for example: grinder + hammer drill + impact wrench), and the combined exposure can push risk higher than you’d expect. Add cold weather, tight deadlines, a death-grip on the handle, or dull accessories, and vibration transfer can increase further.

Hand-Arm Vibration symptoms you should never ignore

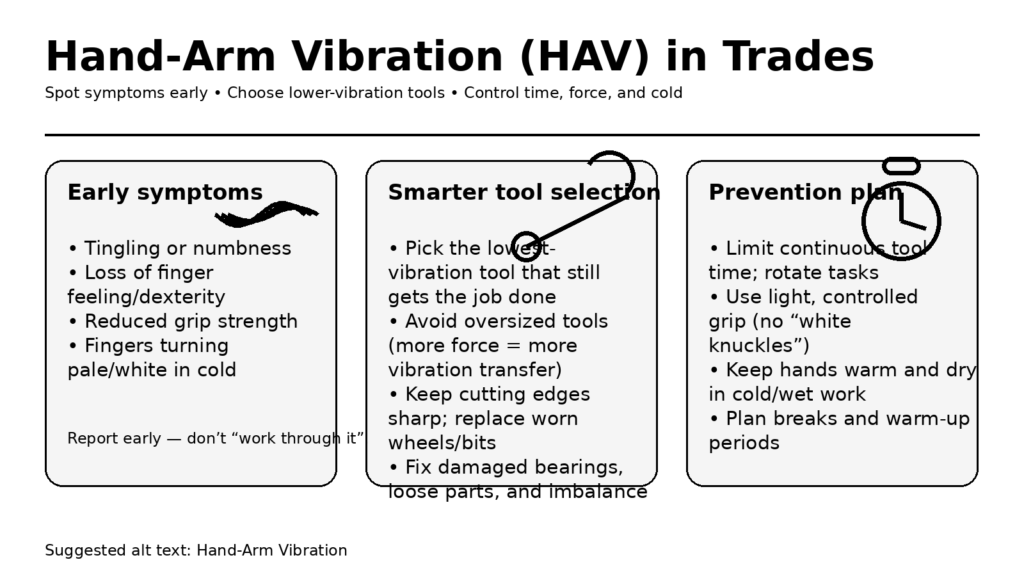

Hand-Arm Vibration symptoms are often “on-and-off” early, which is why workers may brush them off as temporary tingling. But CCOHS lists common reports that include whitening/blanching of fingers in the cold, tingling and loss of sensation, loss of light touch, pain and cold sensations, and reduced grip strength.

A useful way to explain it to crews is: vascular + nerve + function. When HAVS develops, workers may notice numbness, tingling, pain, weakness, reduced dexterity, and episodes of fingers turning pale or waxy white when cold or after vibration exposure.

If someone is reporting frequent numbness, reduced finger control, or blanching attacks, don’t treat it as a “tough it out” issue. Early reporting and exposure reduction matter because some effects can become long-lasting, and prevention is emphasized as essential.

Hand-Arm Vibration exposure limits and what “A(8)” means in practice

Most vibration guidance is discussed as an 8-hour equivalent exposure, written as A(8). The UK HSE regulations set an Exposure Action Value (EAV) of 2.5 m/s² A(8) (where employers should introduce measures to reduce exposure) and an Exposure Limit Value (ELV) of 5.0 m/s² A(8) (which should not be exceeded).

In Ontario construction safety guidance, IHSA references the same concept: EAV 2.5 m/s² and ELV 5 m/s², explaining the EAV is where employers must reduce exposure and the ELV should never be exceeded.

To make this real for supervisors, HSE’s calculator approach also translates exposure into points: EAV aligns with 100 points, and ELV aligns with 400 points, helping you add exposures from multiple tools across a day.

Hand-Arm Vibration tool selection that actually reduces risk

Hand-Arm Vibration prevention starts before the tool hits the jobsite: purchasing and selection. If you only buy based on price or power, you often pay later in injuries, slower work, and lost capability.

Start with these practical selection rules:

- Choose the lowest-vibration tool that can do the job efficiently. IHSA flags selecting the lowest vibrating suitable tool as a key control step.

- Prefer “anti-vibration” tool designs where available, but pair that with maintenance. CCOHS notes some equipment designs (for example anti-vibration chain saws) can significantly reduce acceleration, but only if properly maintained.

- Avoid oversizing tools. A bigger hammer or grinder than needed often forces higher grip, more push force, and longer exposure time.

- Look at manufacturer vibration values (m/s²) and match them to realistic task duration. Even a “lower vibration” tool can be high risk if the task duration is long.

A smart tool strategy also includes alternatives: can you break concrete with a method that reduces handheld vibration exposure (mechanized options, jigs, fixtures, or different processes)? IHSA explicitly recommends looking for alternative methods that eliminate or reduce vibration exposure.

Hand-Arm Vibration “limits” depend on time, grip, cold, and maintenance

Hand-Arm Vibration isn’t just a number on a box. Exposure depends on magnitude + duration, and CCOHS reminds us that grip force affects how much vibration energy enters the hands—meaning “white knuckle” technique can raise risk.

Maintenance is a huge lever you can control. Worn, blunt, or out-of-alignment tools often vibrate more, and CCOHS recommends not using faulty tools and maintaining them properly to reduce risk.

Even simple changes—replacing a worn grinding wheel, keeping cutting edges sharp, checking rotating balance—can reduce vibration and improve productivity.

Cold matters too. CCOHS notes vibration-induced white finger symptoms can be aggravated when hands are exposed to cold.

That means winter work, wet tasks, and early-morning starts can trigger symptoms sooner and more severely unless you plan warmth and breaks.

Hand-Arm Vibration prevention plan using the hierarchy of controls

Hand-Arm Vibration prevention works best when you treat it like any other exposure problem: control it at the source, control the path, and manage exposure time—then use PPE as support (not as the main fix).

1) Engineering and process controls

NIOSH recommends redesigning jobs to minimize vibrating hand tool use and redesigning tools to minimize vibration where elimination isn’t feasible.

On the ground, this can look like choosing different methods, using fixtures/jigs or suspension systems, and improving workstation ergonomics so workers don’t have to death-grip a heavy tool for stability.

2) Administrative controls (time and rotation)

Use exposure budgeting. Track which tasks and tools drive the most vibration and rotate work so one person isn’t on a high-vibration tool for an entire shift. IHSA recommends limiting time exposed and switching tasks through the day.

If you want a practical calculation method, HSE’s exposure calculator shows time-to-reach EAV/ELV and totals across multiple tools.

3) Work practices (skill-based reduction)

CCOHS recommends using a minimum-strength grip consistent with safe tool control, taking rest periods to avoid continuous exposure, resting the tool on the workpiece when possible, and keeping warm.

These are not “soft tips”—they directly reduce vibration transfer and trigger conditions.

4) PPE and warmth (supporting layer)

Gloves can help keep hands warm, which is important for symptom control, but vibration reduction from gloves can be limited. CCOHS notes anti-vibration gloves have limited effectiveness and should not be the only control when hazards aren’t adequately controlled.

Some guidance also stresses choosing gloves that meet relevant anti-vibration standards and avoiding half-finger gloves for that purpose.

A supervisor-ready Hand-Arm Vibration checklist for job sites

Hand-Arm Vibration management becomes repeatable when you make it a weekly routine, not a once-a-year poster.

Use this quick checklist:

- Identify your high-vibration tools/tasks first (grinders, impact tools, hammer drills, chipping hammers, jackhammers).

- Confirm tools are maintained, sharp, balanced, and not damaged.

- Set rotation and break patterns for high-vibration tasks and document them.

- Train crews to recognize numbness/tingling, dexterity loss, blanching, and to report early.

- Plan for warmth controls (dry gloves available, warm-up breaks, keep hands dry in cold/wet work).

- If exposure is frequent, consider health monitoring/surveillance approaches aligned with risk level; NIOSH highlights medical surveillance and education as key parts of control.

If you want this rolled into broader OHSE learning (new worker orientation, hazard awareness, and refresher testing), integrate the topic into your internal training resources and evaluations on OHSE.ca so it stays visible year-round.

When to escalate: early reporting protects careers

Hand-Arm Vibration problems can be underreported because symptoms are intermittent and often show up when hands are cold or wet—conditions that may not appear during a clinic visit. NIOSH notes this underreporting issue and emphasizes prompt attention when prolonged tingling/numbness or blanching signs appear.

Make it normal to report early. The goal isn’t to remove someone from work; the goal is to adjust exposure and methods before the damage becomes harder to reverse. Hand-Arm Vibration

No comments yet