Identify workplace hazards early to ensure a safer, healthier, and more productive environment.

Hazards don’t just cause injuries or illnesses; they disrupt operations and reduce employee morale. Understanding and controlling these hazards is a fundamental OHSE responsibility across all industries.

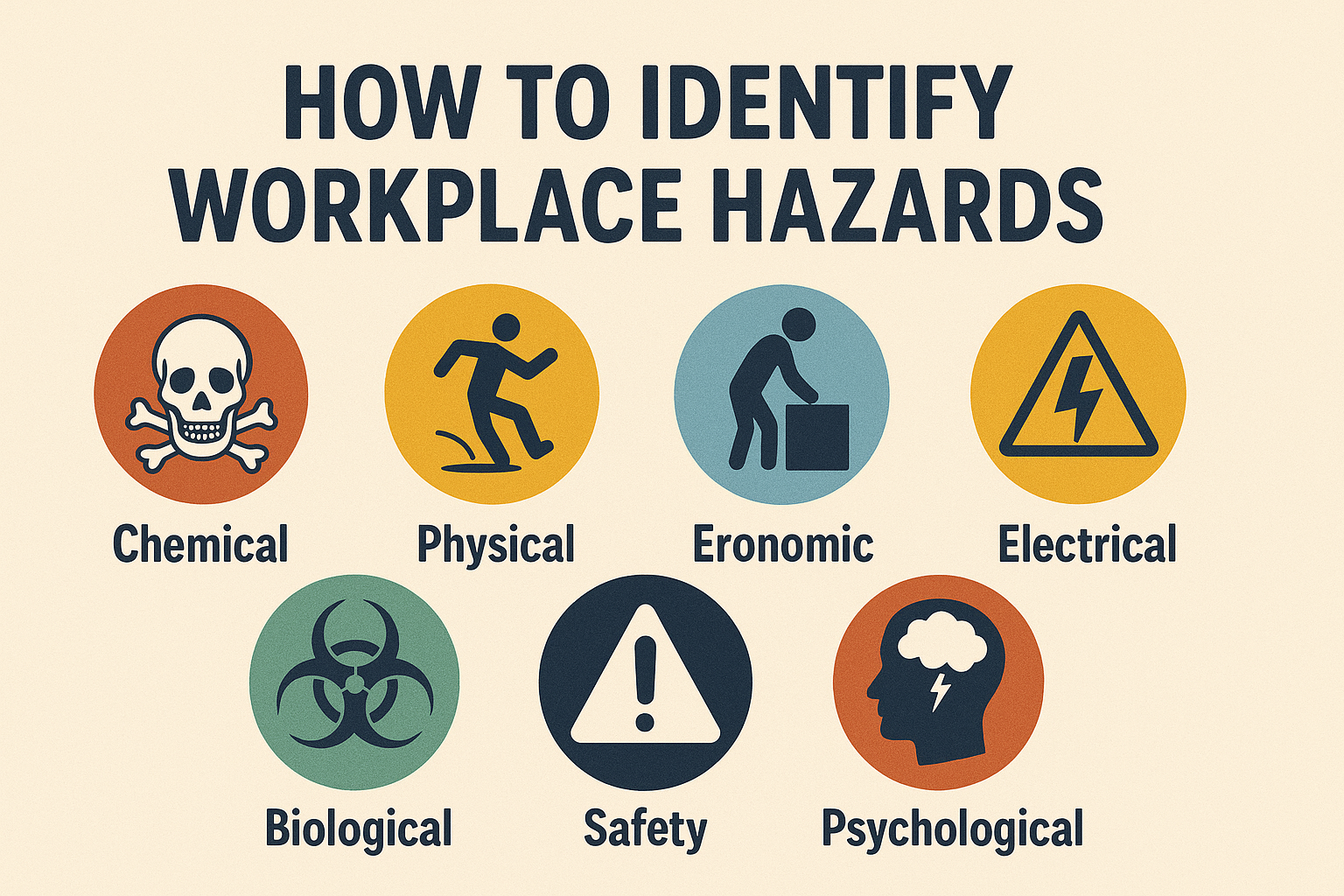

Understanding Workplace Hazards

Hazards are potential sources of harm or adverse health effects.

They can be physical, chemical, biological, ergonomic, or psychosocial. Recognizing the types of hazards is the first step in building a robust occupational health and safety system.

- Physical Hazards: Machinery, noise, radiation, or slip/trip risks.

- Chemical Hazards: Exposure to solvents, fumes, dust, or toxic substances.

- Biological Hazards: Viruses, bacteria, and mold commonly found in healthcare or food environments.

- Ergonomic Hazards: Poor workstation design, repetitive motion, or improper lifting.

- Psychosocial Hazards: Stress, violence, harassment, or job insecurity.

How to Identify Workplace Hazards

Step 1: Conduct Regular Inspections

Routine site inspections are crucial. Walkthroughs should involve safety officers and employee representatives. Use hazard checklists tailored to your specific industry.

Step 2: Analyze Job Tasks

Use Job Hazard Analysis (JHA) to break down tasks and identify potential risks in each step. This is especially effective in high-risk jobs.

Step 3: Review Incident Records

Look into past accidents, near-misses, and complaints. Trends in incident reports often reveal recurring hazards.

Step 4: Consult Employees

Workers often recognize risks that managers overlook. Involving them in safety conversations enhances both reporting and compliance.

Step 5: Monitor Environmental Conditions

Track conditions like air quality, noise, temperature, and lighting. This is especially important in warehouses, labs, and outdoor worksites.

How to Control Workplace Hazards

Once you identify workplace hazards, the next step is to control or eliminate them using the Hierarchy of Controls:

- Elimination: Remove the hazard entirely (e.g., replace a toxic chemical with a safer alternative).

- Substitution: Use less hazardous materials or processes.

- Engineering Controls: Isolate people from hazards (e.g., machine guards, fume hoods).

- Administrative Controls: Change the way people work (e.g., rotating shifts, safety signs, training).

- Personal Protective Equipment (PPE): Used when other controls are not sufficient. Ensure proper fit, training, and maintenance.

Common Examples of Workplace Hazards and Controls

| Hazard Type | Example | Control Measure |

|---|---|---|

| Physical | Wet floors | Anti-slip mats, signage |

| Chemical | Paint fumes | Ventilation, respirators |

| Biological | COVID-19 virus | Hand hygiene, masks, isolation |

| Ergonomic | Repetitive lifting | Adjustable tools, training |

| Psychosocial | Bullying or harassment | Reporting systems, EAP support |

Internal and External Resources

- See our full guide on Proper Waste Segregation

- Learn more about Job Hazard Analysis (DoFollow)

- Get tools from CCOHS.ca to improve your inspection programs (DoFollow)

- Visit OHSE.ca for more Canadian occupational health articles (DoFollow)

Final Thoughts

To create a safe and productive workplace, identify workplace hazards proactively and apply control measures rigorously.

The goal isn’t just compliance, but a culture where safety becomes second nature. Empower your teams with knowledge, tools, and open communication.

Remember: The earlier you identify workplace hazards, the easier they are to control.

No comments yet