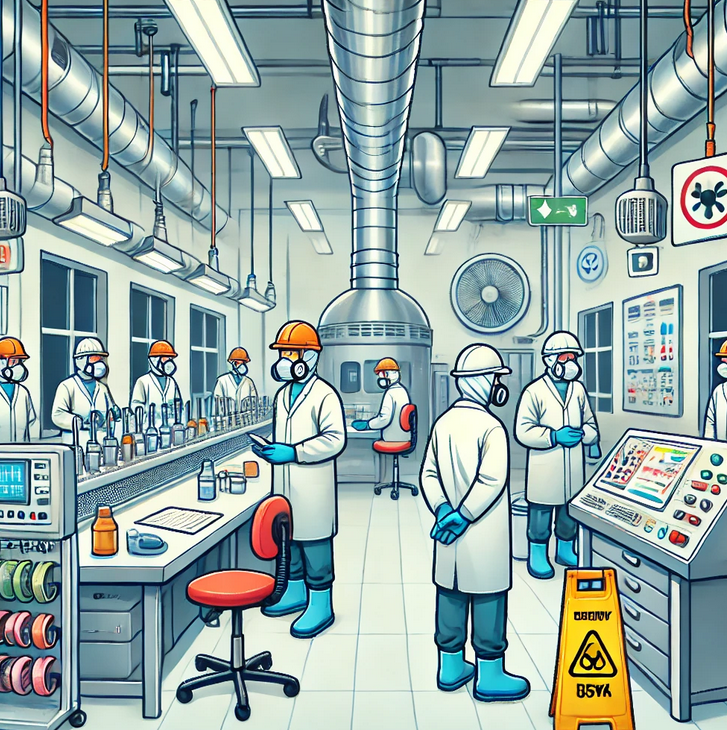

Industrial hygiene plays a crucial role in ensuring workplace safety and health by minimizing the risk of exposure to airborne contaminants. These contaminants, including dust, fumes, gases, and biological hazards, can have significant adverse effects on workers’ health, productivity, and overall well-being.

This article explores the principles, methods, and technologies used in controlling airborne contaminants in industrial settings.

Understanding Airborne Contaminants

Airborne contaminants are particles, gases, or biological agents suspended in the air, which can pose serious health risks when inhaled. Common examples include:

- Dust: Particles from materials like wood, metal, or cement.

- Fumes: Vaporized solids from welding or smelting processes.

- Gases: Toxic or flammable gases like carbon monoxide or nitrogen dioxide.

- Biological Hazards: Mold spores, bacteria, or viruses in confined spaces.

Health Risks

- Short-term exposure can cause irritation to the eyes, nose, and throat.

- Long-term exposure may lead to chronic respiratory issues, lung disease, or even cancer.

Key Principles of Industrial Hygiene

To control airborne contaminants effectively, workplaces must adhere to the core principles of industrial hygiene:

- Anticipation: Identify potential sources of airborne hazards based on work processes.

- Recognition: Understand the nature of the contaminants and their potential effects.

- Evaluation: Measure the concentration of contaminants to assess risk levels.

- Control: Implement strategies to minimize or eliminate exposure.

Methods of Controlling Airborne Contaminants

1. Source Control

Eliminating or reducing contaminants at the source is the most effective method.

- Substitution: Replace hazardous materials with safer alternatives.

Example: Using water-based paints instead of solvent-based ones. - Process Modification: Change procedures to minimize emissions.

Example: Implementing closed systems for chemical handling.

2. Ventilation

Proper ventilation ensures contaminants are removed from the air efficiently.

- Local Exhaust Ventilation (LEV):

- Captures contaminants at the source before they disperse into the workspace.

- Example: Welding hoods and fume extractors.

- General Ventilation:

- Dilutes airborne contaminants throughout the space.

- Example: High-efficiency HVAC systems.

| Ventilation Type | Benefits | Challenges |

|---|---|---|

| Local Exhaust | Targeted control, energy-efficient | Higher installation costs |

| General Ventilation | Covers large areas, easier to install | Less effective for concentrated sources |

3. Personal Protective Equipment (PPE)

When engineering controls are insufficient, PPE serves as the last line of defense.

- Respirators: Filter out particulates, gases, and fumes.

- Types: Disposable masks, half-mask respirators, full-face respirators.

- Face Shields: Protect against splashes and larger airborne particles.

- Gloves and Coveralls: Prevent contact with biological or chemical contaminants.

4. Administrative Controls

Policies and procedures can help limit exposure to contaminants.

- Work Rotation: Reducing the time workers spend in high-contaminant areas.

- Training Programs: Educating employees on risks and proper safety practices.

- Signage and Markings: Clearly label high-risk zones to promote awareness.

5. Air Filtration Systems

Advanced filtration systems remove contaminants from the air.

- HEPA Filters: Capture 99.97% of airborne particles as small as 0.3 microns.

- Activated Carbon Filters: Absorb gases and odors.

- UV Air Purifiers: Neutralize biological hazards like bacteria and viruses.

Monitoring and Evaluation

Continuous monitoring is critical to ensure workplace air quality meets safety standards. Key tools include:

- Air Sampling Devices: Measure concentrations of specific contaminants.

- Real-Time Monitors: Provide immediate feedback on air quality.

- Occupational Exposure Limits (OELs): Ensure compliance with regulatory standards like OSHA or NIOSH guidelines.

Case Study: Controlling Silica Dust in Construction

In the construction industry, silica dust is a common airborne hazard. Strategies to control exposure include:

- Using wet methods to suppress dust during cutting or grinding.

- Employing LEV systems to capture dust at the source.

- Providing workers with N95 respirators when other controls are insufficient.

Results:

- Reduction in respiratory illness cases among workers.

- Improved compliance with silica exposure standards.

Emerging Technologies in Airborne Contaminant Control

- IoT-Enabled Air Quality Sensors:

- Provide real-time data on air quality and alert workers to unsafe conditions.

- AI-Driven Ventilation Systems:

- Automatically adjust airflow based on contaminant levels.

- Nanotechnology Filters:

- Capture ultrafine particles and enhance filtration efficiency.

Monitoring equipment for controlling airborne contaminants

Here are some commonly used monitoring equipment for controlling airborne contaminants in workspaces, categorized by type and purpose:

1. Air Sampling Devices

These devices measure specific airborne contaminants by collecting samples for laboratory analysis.

- Personal Air Samplers:

- Collect air samples directly from a worker’s breathing zone.

- Example: SKC Personal Air Sampling Pump

- Ideal for measuring exposure to dust, gases, and vapors.

- Filter-Based Samplers:

- Use filters to trap particles for analysis.

- Example: Casella Dust Sampling Pump

- Effective for monitoring respirable dust, including silica.

2. Real-Time Air Quality Monitors

These devices provide immediate readings of air quality parameters.

- Particle Counters:

- Measure the concentration of airborne particulates in real-time.

- Example: TSI AeroTrak Portable Particle Counter

- Tracks particles in cleanrooms, industrial spaces, and HVAC systems.

- Gas Detectors:

- Monitor the presence of toxic or flammable gases.

- Example: Dräger X-am 8000 Multigas Detector

- Detects multiple gases, including CO, NO2, and H2S.

3. Continuous Monitoring Systems

These systems provide ongoing air quality assessment in larger areas.

- Fixed Air Quality Monitors:

- Installed in high-risk zones to track contaminants continuously.

- Example: Honeywell Air Quality Sensor

- Monitors VOCs, CO2, and particulate matter.

- IoT-Enabled Systems:

- Combine sensors with real-time data streaming for remote monitoring.

- Example: Aeroqual Series 500

- Offers cloud connectivity for remote air quality management.

4. Biological Contaminant Monitors

These are specialized tools for detecting biological hazards like mold, bacteria, and viruses.

- Bioaerosol Samplers:

- Capture airborne biological particles for lab analysis.

- Example: Merck MAS-100 Air Sampler

- Commonly used in pharmaceutical and healthcare industries.

- UV-C Monitoring Sensors:

- Evaluate the effectiveness of UV air purification systems.

- Example: Sanuvox UV System Monitors

5. Gas-Specific Analyzers

For targeted measurement of individual gases or vapors.

- Carbon Monoxide Detectors:

- Example: Extech CO10 Carbon Monoxide Meter

- Measures CO levels in industrial and confined spaces.

- Example: Extech CO10 Carbon Monoxide Meter

- Volatile Organic Compound (VOC) Detectors:

- Example: RAE Systems MiniRAE 3000

- Provides real-time VOC readings in manufacturing or paint operations.

- Example: RAE Systems MiniRAE 3000

- Oxygen Analyzers:

- Example: Teledyne Analytical Instruments Oxygen Analyzer

- Monitors oxygen levels in confined spaces.

- Example: Teledyne Analytical Instruments Oxygen Analyzer

6. Specialized Dust and Particulate Monitors

Designed for industries like construction, mining, and manufacturing.

- Respirable Dust Monitors:

- Example: Casella Microdust Pro

- Measures airborne dust concentrations in real-time.

- Example: Casella Microdust Pro

- Silica Dust Monitors:

- Example: Trolex XD One

- Specifically designed for monitoring silica exposure on construction sites.

- Example: Trolex XD One

7. Calibration and Verification Equipment

Regular calibration ensures the accuracy of monitoring devices.

- Calibrators for Air Sampling Pumps:

- Example: TSI Primary Calibrator

- Used to verify air sampling flow rates.

- Example: TSI Primary Calibrator

- Gas Calibration Kits:

- Example: Honeywell Gas Detector Calibration Kit

- Ensures gas detectors provide accurate readings.

- Example: Honeywell Gas Detector Calibration Kit

8. Portable Monitors for Field Use

Lightweight devices ideal for mobile or remote settings.

- Multi-Gas Monitors:

- Example: BW Technologies GasAlertMicroClip XL

- Compact and rugged for use in hazardous environments.

- Example: BW Technologies GasAlertMicroClip XL

- Portable Air Quality Monitors:

- Example: Atmotube Pro Portable Air Quality Monitor

- Measures VOCs, particulate matter, and environmental parameters.

- Example: Atmotube Pro Portable Air Quality Monitor

Choosing the Right Equipment

To select the best monitoring equipment for your workspace:

- Identify Contaminants: Understand the types of airborne hazards present.

- Consider the Environment: Choose tools suited for confined spaces, open areas, or cleanrooms.

- Check Standards Compliance: Ensure devices meet OSHA, NIOSH, or other regulatory requirements.

- Invest in Maintenance: Regular calibration and servicing extend the lifespan and reliability of monitoring equipment.

These tools, combined with a proactive approach to industrial hygiene, can significantly enhance workplace safety by controlling airborne contaminants effectively.

Understanding Ventilation Systems in Industrial Hygiene

Ventilation systems are critical components in controlling airborne contaminants and ensuring a safe and healthy working environment. They work by diluting, capturing, or removing hazardous substances from the air, thereby reducing worker exposure to harmful particles, gases, vapors, and biological agents.

Here’s a breakdown of different ventilation systems, their applications, and how they contribute to industrial hygiene:

1. Types of Ventilation Systems

a. Local Exhaust Ventilation (LEV)

- Purpose: Captures contaminants at their source before they disperse into the workplace.

- How It Works:

- A hood or enclosure is placed close to the contaminant source.

- Contaminated air is drawn through ducts and filtered or expelled outside.

- Applications:

- Welding, grinding, and chemical mixing processes where hazardous fumes, dust, or vapors are generated.

- Advantages:

- Highly effective at reducing exposure to specific contaminants.

- Energy-efficient as it minimizes the need for large-scale airflow.

b. General or Dilution Ventilation

- Purpose: Dilutes airborne contaminants by introducing fresh air and exhausting polluted air.

- How It Works:

- Large fans or HVAC systems circulate clean air throughout the workspace.

- Contaminants are dispersed and removed over time.

- Applications:

- Suitable for spaces with low concentrations of airborne hazards.

- Commonly used for heat and odor control.

- Advantages:

- Covers large areas effectively.

- Easier and less expensive to install than LEV.

2. Components of Ventilation Systems

- Hoods: Capture contaminated air at the source (used in LEV systems).

- Ducts: Transport air to and from the workspace.

- Filters and Scrubbers: Remove particulates, gases, or biological contaminants from the air.

- Fans: Move air through the system.

- Exhaust Outlets: Release treated air outside the workspace.

3. Key Design Considerations

a. Airflow Rate

- Measured in cubic feet per minute (CFM), the airflow rate determines how effectively the system removes contaminants.

b. Contaminant Type

- The system must be tailored to handle specific contaminants, such as:

- Particulates (dust, fibers)

- Fumes and vapors (welding fumes, solvents)

- Gases (carbon monoxide, ammonia)

c. Workspace Size

- The size and layout of the area influence the choice of system, airflow requirements, and placement of components.

d. Maintenance Needs

- Proper maintenance, including filter replacement and duct cleaning, ensures consistent performance and compliance with safety standards.

4. Advanced Ventilation Technologies

a. Smart Ventilation Systems

- Equipped with sensors to monitor air quality in real-time.

- Automatically adjust airflow based on contaminant levels.

b. Energy Recovery Ventilators (ERVs)

- Capture and reuse heat from exhaust air to improve energy efficiency.

c. High-Efficiency Particulate Air (HEPA) Filters

- Remove 99.97% of airborne particles as small as 0.3 microns.

- Ideal for cleanrooms, healthcare facilities, and environments with sensitive processes.

5. Benefits of Effective Ventilation Systems

- Reduced Contaminant Exposure: Improves air quality and minimizes respiratory risks.

- Enhanced Worker Comfort: Regulates temperature, humidity, and odors.

- Regulatory Compliance: Ensures adherence to OSHA, NIOSH, and EPA standards.

- Increased Productivity: A healthier environment promotes better focus and reduced absenteeism.

6. Challenges and Solutions

a. Installation Costs

- Challenge: High initial costs for LEV systems and advanced filters.

- Solution: Assess cost-effectiveness over time due to reduced health risks and operational efficiency.

b. Maintenance Requirements

- Challenge: Regular maintenance is needed to avoid system inefficiencies.

- Solution: Implement routine inspections and servicing schedules.

c. Inadequate Design

- Challenge: Poorly designed systems may fail to capture or dilute contaminants effectively.

- Solution: Work with qualified industrial hygiene engineers for proper design and implementation.

7. Choosing the Right Ventilation System

To select the most appropriate system:

- Identify Hazards: Determine the type and source of contaminants.

- Evaluate Workplace Needs: Assess the size, layout, and processes of the workspace.

- Regulatory Requirements: Ensure compliance with local and international standards.

- Consult Experts: Collaborate with industrial hygienists or ventilation engineers.

Examples of Airborne Contaminants

Airborne contaminants refer to particles, gases, vapors, or biological agents suspended in the air that can pose health risks when inhaled. Here’s a breakdown of common airborne contaminants categorized by type:

1. Particulate Matter (PM)

a. Dust

- Source: Generated from cutting, grinding, or handling materials like wood, metal, or cement.

- Examples:

- Silica dust from construction and mining activities.

- Wood dust in furniture manufacturing.

b. Fumes

- Source: Vaporized materials that condense into fine particles.

- Examples:

- Welding fumes containing metals like iron, manganese, or chromium.

- Soldering fumes in electronics assembly.

c. Fibers

- Source: Materials that release elongated particles.

- Examples:

- Asbestos fibers from insulation and older construction materials.

- Synthetic fibers from textiles and carpets.

d. Mists

- Source: Liquid droplets suspended in air, often from sprays or industrial processes.

- Examples:

- Paint mists in spray painting.

- Oil mists from machining operations.

2. Gases and Vapors

a. Toxic Gases

- Examples:

- Carbon Monoxide (CO): Released from combustion engines or faulty heating systems.

- Nitrogen Dioxide (NO2): Emitted during welding or combustion processes.

- Ammonia (NH3): Found in refrigeration systems and cleaning products.

b. Vapors

- Source: Evaporation of liquids into the air.

- Examples:

- Solvent vapors from paints, adhesives, and cleaning agents (e.g., acetone, toluene).

- Gasoline or fuel vapors in transportation and refueling areas.

c. Flammable Gases

- Examples:

- Methane (CH4) from landfill sites and gas pipelines.

- Hydrogen (H2) in industrial settings.

3. Biological Contaminants

a. Microorganisms

- Examples:

- Bacteria such as Legionella in poorly maintained water systems.

- Mold spores in damp or poorly ventilated spaces.

- Viruses, such as influenza or SARS-CoV-2, in healthcare or crowded environments.

b. Allergens

- Examples:

- Pollen from plants entering indoor spaces.

- Dust mites in poorly cleaned areas.

c. Bioaerosols

- Examples:

- Aerosols containing bodily fluids in hospitals.

- Animal dander in veterinary clinics or pet-related industries.

4. Chemicals

a. Volatile Organic Compounds (VOCs)

- Examples:

- Formaldehyde in building materials and furniture.

- Benzene in petrochemical industries.

b. Pesticides

- Source: Used in agriculture and pest control operations.

- Examples:

- Insecticides and herbicides sprayed in farming areas.

c. Acid Gases

- Examples:

- Sulfur Dioxide (SO2) from industrial processes like smelting.

- Hydrochloric Acid (HCl) vapors from chemical manufacturing.

5. Combustion Byproducts

- Examples:

- Soot and particulate matter (PM2.5) from vehicle exhaust.

- Polycyclic Aromatic Hydrocarbons (PAHs) from burning organic material.

- Smoke from industrial fires or open burning.

6. Radionuclides

- Source: Radioactive materials released into the air.

- Examples:

- Radon gas in basements or mining operations.

- Uranium dust in nuclear facilities.

7. Specific Industry-Related Contaminants

Construction Industry

- Silica dust, asbestos, and cement particles.

Healthcare Industry

- Biological hazards like viruses, bacteria, and disinfectant fumes.

Manufacturing Industry

- Metal fumes, VOCs, and plastic vapors.

Agriculture

- Pesticide mists, organic dust, and bioaerosols.

Health Implications of Airborne Contaminants

- Short-Term Effects:

- Eye, nose, and throat irritation.

- Dizziness, headaches, or nausea.

- Long-Term Effects:

- Chronic respiratory diseases, such as asthma or silicosis.

- Cardiovascular issues and cancer from prolonged exposure to toxic substances.

Understanding these contaminants and their sources is essential for implementing effective control measures in industrial hygiene practices, such as ventilation, air filtration, and protective equipment.

Industrial Hygiene Principles

Industrial hygiene focuses on identifying, evaluating, and controlling workplace environmental factors that can affect the health and safety of workers. The principles of industrial hygiene guide professionals in preventing illness and injury due to exposure to hazardous conditions in the workplace. These principles are essential for creating safe and healthy working environments.

1. Anticipation of Hazards

- Definition: Predicting potential hazards that may arise from work processes, materials, or environmental conditions.

- Key Actions:

- Review plans for new processes or equipment to identify potential risks.

- Conduct pre-assessments for new materials, such as chemicals or tools.

- Understand trends in workplace injuries or illnesses to proactively address emerging risks.

Example: Anticipating respiratory risks from silica dust during construction activities.

2. Recognition of Hazards

- Definition: Identifying existing hazards in the workplace by analyzing processes, tasks, and materials.

- Key Actions:

- Perform regular workplace inspections.

- Use job hazard analyses (JHAs) to pinpoint hazardous conditions.

- Identify physical (noise, heat), chemical (fumes, vapors), biological (bacteria, mold), and ergonomic hazards.

Example: Recognizing excessive noise levels in a factory that could lead to hearing loss.

3. Evaluation of Hazards

- Definition: Measuring and assessing the severity and exposure levels of identified hazards.

- Key Actions:

- Use tools and equipment, such as air sampling pumps or noise meters, to quantify exposures.

- Compare measurements against regulatory exposure limits, such as OSHA’s Permissible Exposure Limits (PELs).

- Analyze exposure duration, frequency, and intensity to determine risk levels.

Example: Using air quality monitors to evaluate worker exposure to welding fumes.

4. Control of Hazards

- Definition: Implementing measures to reduce or eliminate identified hazards, using a hierarchy of controls.

a. Elimination/Substitution

- Remove the hazard or replace it with a less dangerous alternative.

- Example: Substituting a toxic solvent with a water-based alternative.

b. Engineering Controls

- Modify equipment or processes to reduce exposure.

- Example: Installing local exhaust ventilation (LEV) to capture fumes at the source.

c. Administrative Controls

- Change work practices or schedules to limit exposure.

- Example: Rotating employees to minimize time spent in high-exposure areas.

d. Personal Protective Equipment (PPE)

- Provide protective gear to workers as a last line of defense.

- Example: Equipping workers with respirators in environments with airborne contaminants.

5. Communication and Training

- Definition: Educating employees about workplace hazards, proper safety protocols, and protective measures.

- Key Actions:

- Conduct regular safety training sessions.

- Use clear signage to highlight hazardous areas or materials.

- Develop materials in multiple languages for diverse workforces.

Example: Training employees on proper handling and storage of hazardous chemicals.

6. Continuous Monitoring

- Definition: Regularly observing and measuring workplace conditions to ensure the effectiveness of controls and compliance with standards.

- Key Actions:

- Install monitoring devices, such as real-time gas detectors or noise dosimeters.

- Conduct periodic audits and reassessments.

- Maintain detailed records of hazard evaluations and control measures.

Example: Using continuous air quality monitoring in a confined space to detect changes in gas concentrations.

7. Compliance with Regulations

- Definition: Ensuring workplace practices meet or exceed local, national, and international safety standards.

- Key Actions:

- Familiarize with regulations such as OSHA, NIOSH, or EU Directives.

- Keep up-to-date with changes in safety standards.

- Implement measures to comply with permissible exposure limits and other legal requirements.

Example: Ensuring proper labeling and storage of hazardous materials as per OSHA’s Hazard Communication Standard.

8. Documentation and Reporting

- Definition: Maintaining detailed records of workplace assessments, incidents, and control measures for accountability and continuous improvement.

- Key Actions:

- Log inspection results, exposure levels, and training sessions.

- Use records to identify trends or gaps in safety protocols.

- Share reports with stakeholders, including employees and regulatory bodies.

Example: Keeping a log of PPE distribution and maintenance schedules.

9. Collaboration and Stakeholder Engagement

- Definition: Working with employees, management, and external experts to enhance workplace safety.

- Key Actions:

- Involve workers in identifying hazards and suggesting solutions.

- Partner with industrial hygiene consultants for specialized assessments.

- Engage management to secure resources for implementing controls.

Example: Collaborating with employees to redesign workstations for better ergonomics.

10. Continuous Improvement

- Definition: Regularly evaluating and upgrading industrial hygiene programs to address evolving risks and improve effectiveness.

- Key Actions:

- Implement feedback from employees and incident reports.

- Introduce new technologies, such as AI-powered safety monitoring systems.

- Conduct annual reviews of industrial hygiene policies.

Example: Upgrading air filtration systems to handle increased particulate matter in a growing facility.

Conclusion

Industrial hygiene is the cornerstone of workplace safety, ensuring that hazards are not only identified but effectively controlled to protect workers’ health and productivity. By adhering to core principles such as hazard anticipation, evaluation, and control, organizations can create a safer work environment while fostering compliance with regulatory standards.

The integration of modern technologies, such as real-time monitoring and advanced ventilation systems, further empowers businesses to stay proactive in managing airborne contaminants and other occupational risks.

As workplaces evolve, continuous improvement and stakeholder collaboration remain crucial for successful industrial hygiene programs. Employers must stay informed about emerging risks, implement innovative solutions, and regularly train employees to ensure the effectiveness of safety measures.

To explore more about industrial hygiene practices and regulations, consider resources from OSHA’s Industrial Hygiene Guidelines and AIHA’s Industrial Hygiene Standards. By prioritizing health and safety, companies can safeguard their workforce and pave the way for a sustainable and productive future.