Needle stick injury prevention is not just a procedural requirement—it’s a critical element of worker safety in healthcare and related fields.

At first glance, a needle prick may seem minor, but it carries the potential for severe health consequences.

From the risk of bloodborne pathogens to long-term mental stress, the dangers are real.

This article delves into practical prevention strategies, best practices, and safety solutions to help mitigate the risks associated with needle stick injuries.

Why Needle Stick Injuries Are a Big Risk

Needle stick injuries (NSIs) can expose healthcare workers to bloodborne viruses such as Hepatitis B, Hepatitis C, and HIV. According to the World Health Organization (WHO), over 2 million occupational exposures occur globally each year.

Even a small puncture from a contaminated needle can transmit infectious diseases, making it a high-risk event in both clinical and non-clinical environments.

Beyond physical health, the psychological burden of waiting for test results post-exposure adds another layer of harm.

Common Causes of Needle Stick Injuries

Understanding the root causes is crucial for effective needle stick injury prevention. The most common include:

- Recapping used needles

- Improper disposal of sharps

- Lack of training on safe handling

- Overcrowded workspaces

- Distractions and fatigue

These factors often overlap in high-pressure settings like emergency rooms, outpatient clinics, and long-term care facilities.

High-Risk Professions

While healthcare is the most affected sector, many others face similar risks:

- Nurses and doctors

- Phlebotomists

- Laboratory technicians

- Tattoo artists

- Sanitation workers

- Veterinarians

Facilities such as dental clinics, hospitals, and blood donation centers should have rigorous needle stick prevention protocols.

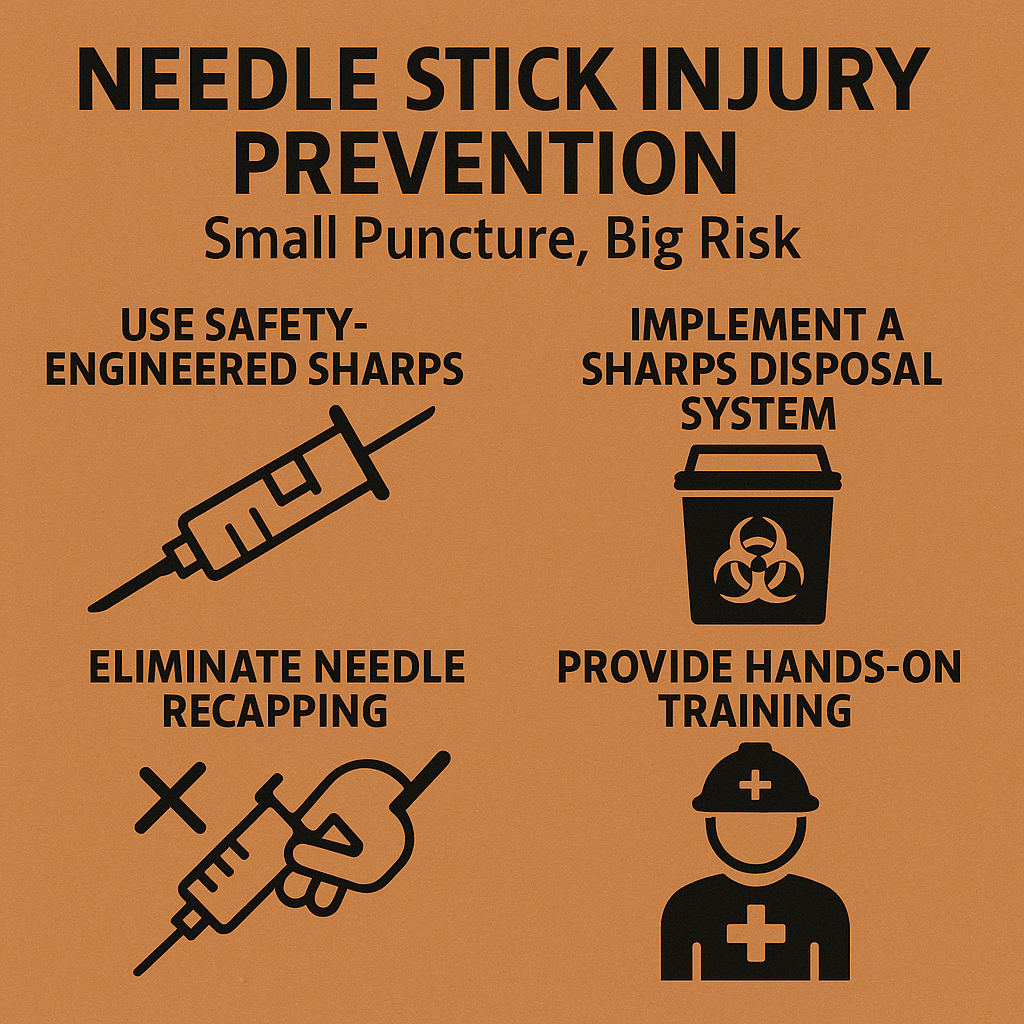

Proven Strategies for Needle Stick Injury Prevention

Here are actionable measures every organization should enforce:

Use Safety-Engineered Sharps

Safety devices like retractable needles, sheathing syringes, and needleless IV systems are game-changers.

According to CDC guidelines, using safety-engineered devices significantly reduces exposure incidents.

Implement a Sharps Disposal System

Every sharp object must be discarded in clearly labeled, puncture-resistant containers. These should be:

- Available at the point of use

- Not overfilled (max ¾ capacity)

- Disposed of by trained personnel

Regular audits can identify misuse or improper placement of containers.

Eliminate Needle Recapping

Recapping is one of the leading causes of NSIs. Establish a clear “No Recapping” policy, and include visual reminders in all procedure rooms and labs.

Provide Hands-On Training

All staff—new and existing—should undergo mandatory safety training. Topics must include:

- Safe handling and disposal

- Post-exposure protocols

- Using safety-engineered devices

Training refreshers should occur annually or after any exposure incident.

Post-Exposure Action Plan

Despite preventive measures, exposures may still happen. Here’s a basic protocol:

- Immediately wash the area with soap and water.

- Report the incident to a supervisor or OH&S representative.

- Fill out an incident report and document details.

- Seek medical evaluation for risk assessment and possible prophylaxis.

- Follow up for lab tests at regular intervals (e.g., 6 weeks, 3 months, 6 months).

Organizations must maintain a clear, confidential, and prompt response system for handling exposures.

Psychological Impact and Support

The mental toll following a needle stick injury should not be underestimated. Anxiety, sleep disturbances, and fear of stigma are common. Employers must provide:

- Access to counseling services

- Peer support groups

- Reassurance of confidentiality

- Periodic check-ins by OHSE professionals

Building a psychologically safe environment reduces absenteeism and builds resilience in the workforce.

Legal and Regulatory Framework

Organizations have a legal obligation to protect employees under occupational health and safety laws. In Canada, for example, provincial OHSA regulations require:

- Risk assessments for sharps use

- Training records

- Use of engineered controls

Employers must consult standards such as those from CSA Group and incorporate national guidelines from OHSE.ca and Canadian Centre for Occupational Health and Safety (CCOHS).

Needle stick injury prevention should be integrated into your existing workplace safety program. Consider:

- Regular toolbox talks on sharps safety

- Safety committee reviews after every incident

- Adding needle stick prevention to your digital SOP library

- Internal reporting dashboards to track trends

Linking to internal compliance logs, incident reports, or training portals keeps everyone aligned.

Commit to Needle Stick Injury Prevention

Needle stick injury prevention may start with a small puncture, but the risk is too significant to ignore. With the right tools, training, and culture of safety, organizations can eliminate these preventable injuries.

Safety is not just compliance—it’s a commitment to your workforce’s health and peace of mind.

No comments yet