PPE stands for Personal Protective Equipment, a cornerstone of workplace safety across industries. Whether in construction, healthcare, manufacturing, or laboratories, PPE provides the critical last line of defense against hazards that could lead to injuries, illnesses, or even fatalities.

While engineering controls and safe work practices aim to reduce risks, PPE ensures that when hazards remain, workers still have essential protection.

What Does PPE Stand For?

At its core, PPE stands for Personal Protective Equipment, which refers to clothing, gear, or devices designed to protect workers from workplace hazards.

These hazards may include physical dangers like falling objects, chemical exposures, biological risks, or environmental conditions such as heat, cold, and noise. PPE acts as a protective barrier between the worker and the hazard.

According to the Occupational Safety and Health Administration (OSHA), employers are legally required to provide appropriate PPE when hazards cannot be eliminated through safer methods.

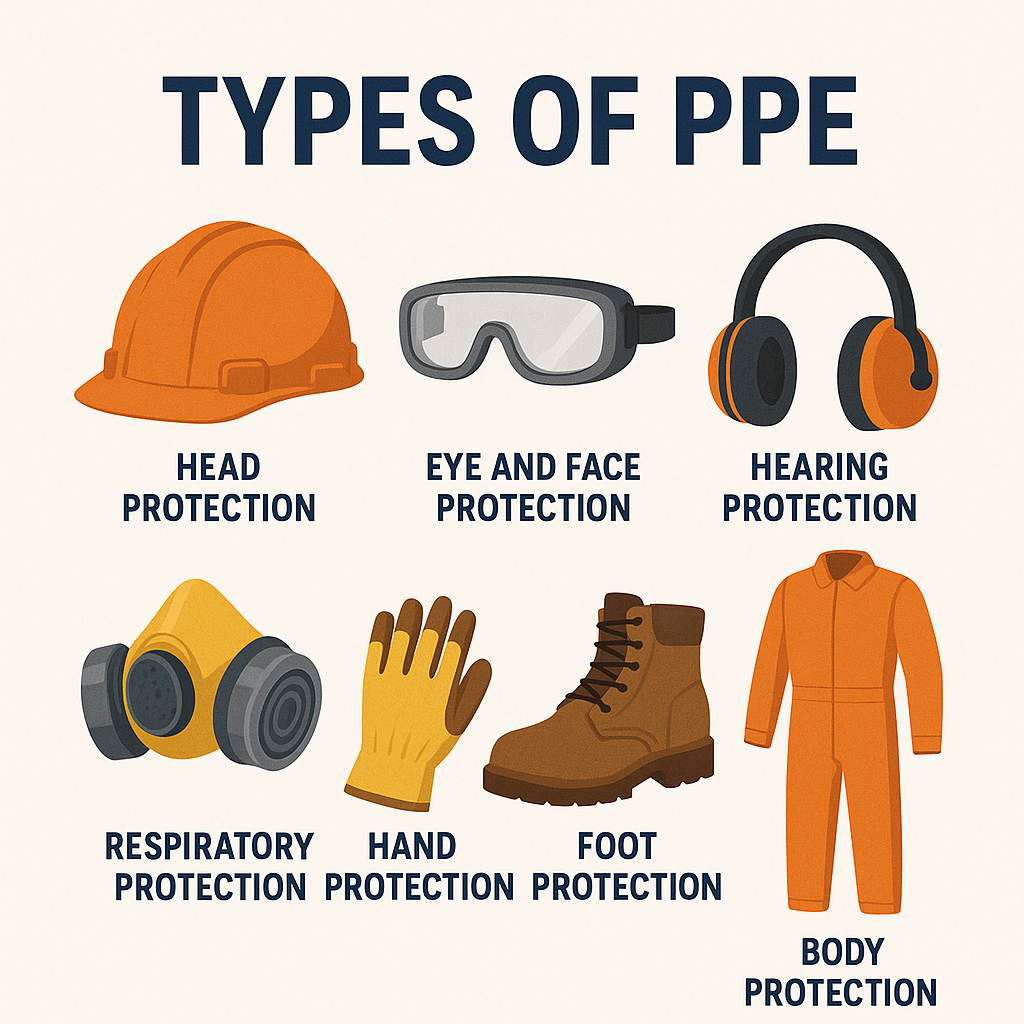

Types of PPE

The scope of PPE is vast, but it generally falls into several categories:

Head Protection

Hard hats protect workers from falling objects, electrical shock, and head injuries in construction and industrial sites.

Eye and Face Protection

Safety glasses, goggles, and face shields prevent injuries from flying debris, chemicals, or sparks.

Hearing Protection

Earplugs and earmuffs safeguard workers from noise-induced hearing loss in loud environments such as factories and airports.

Respiratory Protection

Respirators, masks, and SCBA (self-contained breathing apparatus) protect against dust, fumes, gases, and infectious diseases. Learn more in our detailed guide on Respiratory Protection and VOC Exposure.

Hand Protection

Gloves—ranging from cut-resistant to chemical-resistant types—prevent injuries and burns.

Foot Protection

Safety boots with reinforced toes and slip-resistant soles protect from crushing, punctures, and slips.

Body Protection

Coveralls, flame-resistant clothing, and chemical suits shield against harmful splashes, burns, and extreme temperatures.

Fall Protection

Harnesses, lanyards, and lifelines protect workers at heights from falls, one of the leading causes of workplace fatalities.

Why PPE Stands For More Than Just Equipment

While PPE stands for Personal Protective Equipment, in practice, it represents a commitment to safety culture.

PPE alone is not enough; workers must be trained in its correct use, care, and limitations. Ill-fitting or misused PPE can reduce effectiveness and create a false sense of security.

For example, healthcare workers wearing N95 respirators must undergo fit testing to ensure an airtight seal. In construction, a safety harness must be attached to an anchor point at all times.

Without these practices, PPE fails to provide adequate protection.

Limitations of PPE

Although PPE is vital, it is considered the last line of defense. Engineering controls (like machine guards) and administrative controls (like shift rotations) should come first.

PPE does not eliminate hazards but rather reduces the risk of harm when exposure occurs.

Moreover, comfort and compliance are ongoing challenges. Workers may be tempted to skip PPE due to heat, restricted movement, or perceived inconvenience, which is why leadership must enforce proper use through training and supervision.

Global Standards for PPE

International bodies have set regulations and standards for PPE to ensure quality and consistency:

- OSHA (USA): Establishes employer responsibilities regarding PPE.

- CSA (Canada): Provides detailed standards for hard hats, protective footwear, and more.

- ISO (International): Sets global benchmarks for PPE design and testing.

- European Union (CE Mark): Requires compliance with PPE Regulation (EU) 2016/425.

Employers should only purchase certified PPE to guarantee effectiveness.

PPE in Different Industries

- Healthcare: Gloves, gowns, masks, and face shields protect against infections.

- Construction: Helmets, boots, gloves, and harnesses prevent common site injuries.

- Manufacturing: Eye protection, respirators, and ear protection mitigate chemical and noise hazards.

- Mining and Oil & Gas: Full-body suits, helmets, and respiratory systems protect against toxic gases and explosions.

Best Practices for PPE

- Hazard Assessment: Identify risks before selecting PPE.

- Proper Training: Ensure workers know how to wear, adjust, and maintain equipment.

- Regular Inspections: Damaged PPE should be replaced immediately.

- Worker Involvement: Engage workers in choosing comfortable PPE to increase compliance.

- Integration: Make PPE part of a broader health and safety management system.

For detailed safety program design, see our article on Training and Safety Awareness.

Conclusion

In summary, PPE stands for Personal Protective Equipment, but in reality, it stands for much more: a commitment to protecting lives and fostering a safety-first workplace culture.

From helmets to respirators, PPE remains one of the most powerful tools in reducing workplace injuries. Employers and workers alike must recognize PPE not as an option, but as a necessity.

When worn correctly and supported by proper training, PPE stands for safety, resilience, and responsibility in every workplace.

No comments yet