WHMIS / GHS Requirements are essential for any employer or worker who handles hazardous products in Canada. Understanding these requirements isn’t just about legal compliance—it’s about protecting people, reducing environmental risks, and ensuring smooth operations.

At the start of any safety program that involves chemicals, you need a clear grasp of the WHMIS / GHS Requirements that define labeling, Safety Data Sheets (SDS), worker training, and hazard communication.

This guide will help you understand what’s required, why it matters, and how to implement an effective system in your workplace.

- What Are WHMIS / GHS Requirements?

- Why WHMIS / GHS Requirements Matter

- Classification Under WHMIS / GHS Requirements

- WHMIS / GHS Requirements for Labels

- Safety Data Sheets (SDS) Requirements

- WHMIS / GHS Training Requirements

- Employer and Worker Responsibilities

- Adapting WHMIS / GHS Requirements for Your Workplace

- Aligning with Global Standards

- The Role of Safety Committees in WHMIS / GHS Compliance

- Continuous Improvement and Review

- Conclusion: WHMIS / GHS Requirements for Safer Workplaces

What Are WHMIS / GHS Requirements?

WHMIS stands for Workplace Hazardous Materials Information System, Canada’s national system for providing information on the safe use of hazardous products.

GHS is the Globally Harmonized System of Classification and Labelling of Chemicals, an international framework developed by the United Nations. Canada’s WHMIS was updated in 2015 to align with GHS, and the system is now often called WHMIS 2015.

The core WHMIS / GHS Requirements include:

- Classification of hazardous products

- Labels with standardized elements and pictograms

- Safety Data Sheets (SDS) with detailed hazard information

- Worker education and training

This harmonized approach ensures consistent communication about hazards across industries and borders.

Why WHMIS / GHS Requirements Matter

A proper understanding of WHMIS / GHS Requirements is essential for reducing injuries, illnesses, and environmental damage.

Hazardous products are found in nearly every workplace—from cleaning chemicals in offices to industrial solvents in manufacturing. Misuse can cause:

- Burns, respiratory illnesses, or poisonings

- Fires and explosions

- Long-term environmental harm

According to Health Canada (DoFollow), WHMIS helps ensure that workers have the right information to protect themselves and others.

Classification Under WHMIS / GHS Requirements

Classification is the first step in meeting WHMIS / GHS Requirements. Suppliers and manufacturers must assess the hazards of their products and assign them to standardized classes and categories.

Examples of hazard classes:

- Flammable gases or liquids

- Acute toxicity (oral, dermal, inhalation)

- Skin corrosion/irritation

- Carcinogenicity

By classifying products consistently, WHMIS / GHS ensures that users understand the risks before they handle them.

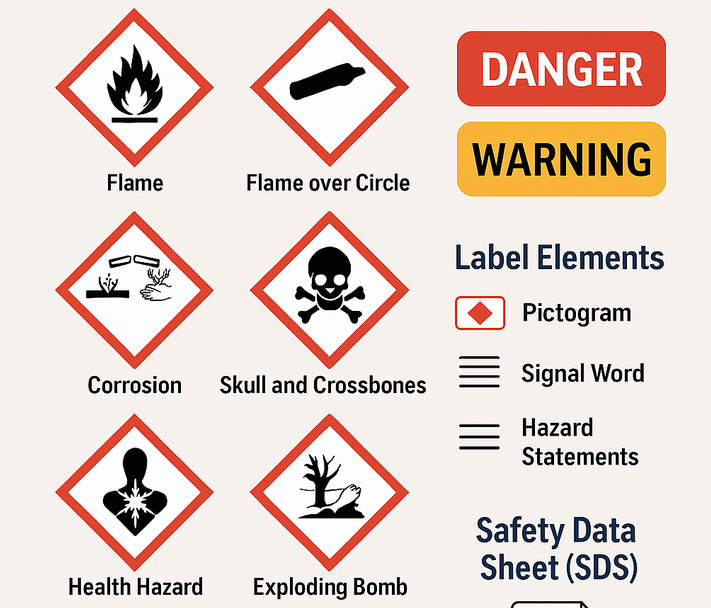

WHMIS / GHS Requirements for Labels

Labels are a central part of WHMIS / GHS Requirements, serving as the first warning for workers.

A compliant WHMIS label includes:

- Product identifier

- Pictograms (e.g., flame, skull and crossbones)

- Signal word (“Danger” or “Warning”)

- Hazard statements (e.g., “Causes skin irritation”)

- Precautionary statements (e.g., “Wear protective gloves”)

- Supplier identifier

Labels must be clear, in English and French, and placed prominently on containers.

Failure to follow labeling requirements can result in fines and, more importantly, accidents. WorkSafeBC (DoFollow) provides detailed provincial guidance on labeling and other WHMIS rules.

Safety Data Sheets (SDS) Requirements

WHMIS / GHS Requirements mandate that every hazardous product has a Safety Data Sheet (SDS).

The SDS is a technical document with 16 standardized sections, including:

- Identification

- Hazard identification

- Composition/information on ingredients

- First-aid measures

- Fire-fighting measures

- Accidental release measures

- Handling and storage

- Exposure controls/Personal protection

- Physical and chemical properties

- Stability and reactivity

- Toxicological information

12–16. Other data (including transport, regulatory info, etc.)

Employers must ensure SDS are:

- Readily available to workers (paper or electronic)

- Up to date (within three years or when new information becomes available)

This level of detail supports safe handling, storage, and emergency response.

WHMIS / GHS Training Requirements

Training is a cornerstone of WHMIS / GHS Requirements. Even with perfect labels and SDS, workers must know how to use them.

Employers are legally required to provide:

- General WHMIS training on symbols, labels, SDS, hazard classes

- Workplace-specific training on procedures, protective equipment, spill response, and emergency plans

For example, a cleaner must know how to read labels, locate SDS, and wear gloves or goggles as required. A warehouse worker handling flammable solvents must know safe storage practices and fire emergency protocols.

Employer and Worker Responsibilities

WHMIS / GHS Requirements clearly assign responsibilities to both employers and workers.

Employers must:

- Ensure hazardous products are properly labeled

- Make SDS accessible at all times

- Provide and document worker training

- Review training needs annually or when new products arrive

Workers must:

- Participate in training

- Follow safe work procedures

- Understand labels and SDS before using products

- Report missing labels or SDS

This shared responsibility model is central to Canada’s occupational health and safety laws. For practical advice on building effective training programs, see our Training and Safety Awareness article.

Adapting WHMIS / GHS Requirements for Your Workplace

Every workplace is different, so employers should customize their approach to WHMIS / GHS Requirements:

- Inventory hazardous products: Keep an updated list.

- Assign responsibilities: Designate who maintains labels/SDS and trains staff.

- Audit your program: Look for missing labels or expired SDS.

- Update procedures: As products or regulations change.

For many companies, a WHMIS program is part of a broader safety management system that includes hazard assessments, emergency planning, and health monitoring.

Aligning with Global Standards

GHS was created to make hazard communication consistent worldwide. Canada’s adoption through WHMIS / GHS Requirements means your labeling and SDS will be recognized in other GHS-participating countries.

This consistency:

- Simplifies import/export compliance

- Improves understanding among multilingual or international workers

- Reduces training costs for global companies

Global alignment also supports environmental goals by ensuring that hazard information travels with products across borders.

The Role of Safety Committees in WHMIS / GHS Compliance

Joint Health and Safety Committees (JHSCs) play a key role in many workplaces:

- Reviewing hazardous product inventories

- Assessing training effectiveness

- Inspecting for missing labels or SDS

- Consulting on emergency procedures

Including WHMIS / GHS Requirements in your regular committee meetings ensures ongoing compliance and safer workplaces.

Continuous Improvement and Review

WHMIS / GHS Requirements aren’t a “set it and forget it” obligation. Regulations evolve, products change, and worker turnover requires ongoing training.

Employers should:

- Review training annually

- Audit labels and SDS quarterly

- Monitor changes to WHMIS legislation

- Encourage worker feedback

Continuous improvement is a best practice in occupational health and safety management.

Conclusion: WHMIS / GHS Requirements for Safer Workplaces

Meeting WHMIS / GHS Requirements is essential to protect workers, avoid fines, and support a strong safety culture.

By understanding classification, labels, SDS, and training, you can reduce injuries, improve environmental outcomes, and boost your reputation as a responsible employer.

For more safety articles and tools, visit OHSE.ca—and make WHMIS / GHS Requirements a foundation of your safety program.

No comments yet