Wrist Injuries in Rebar Work, often called rod busters, are the backbone of concrete construction. They bend, cut, and tie reinforcing steel (rebar) into place so that structures like bridges, towers, and foundations can withstand immense forces.

But while their work strengthens concrete, it often weakens their own hands and wrists. Preventing hand and wrist injuries in rebar work is one of the most important aspects of occupational safety in this trade.

Why Hand and Wrist Injuries Are So Common in Rebar Work

Unlike many construction jobs, rebar work is almost entirely manual. Workers handle steel rods, binding wire, and tying tools for hours every day.

Hazards include:

- Repetitive motion: tying thousands of knots per shift.

- Forceful gripping: constant pressure on the wrist and forearm.

- Sharp edges: cuts and punctures from steel and wire.

- Vibration: from powered tying or cutting tools.

According to OSHA, musculoskeletal disorders (MSDs) such as carpal tunnel syndrome and tendonitis are common in repetitive, forceful jobs like rebar tying.

The Hidden Costs of Hand and Wrist Injuries

Injuries in this trade don’t just cause temporary discomfort. They can lead to:

- Lost productivity from missed workdays.

- Permanent nerve damage that ends careers.

- Workers’ compensation claims that impact both employers and employees.

- Reduced grip strength that makes basic tasks painful.

For rebar workers, strong hands aren’t optional—they’re essential. That’s why preventing hand and wrist injuries in rebar work must be a top OHSE priority.

Best Practices to Prevent Hand and Wrist Injuries

1. Provide the Right Gloves

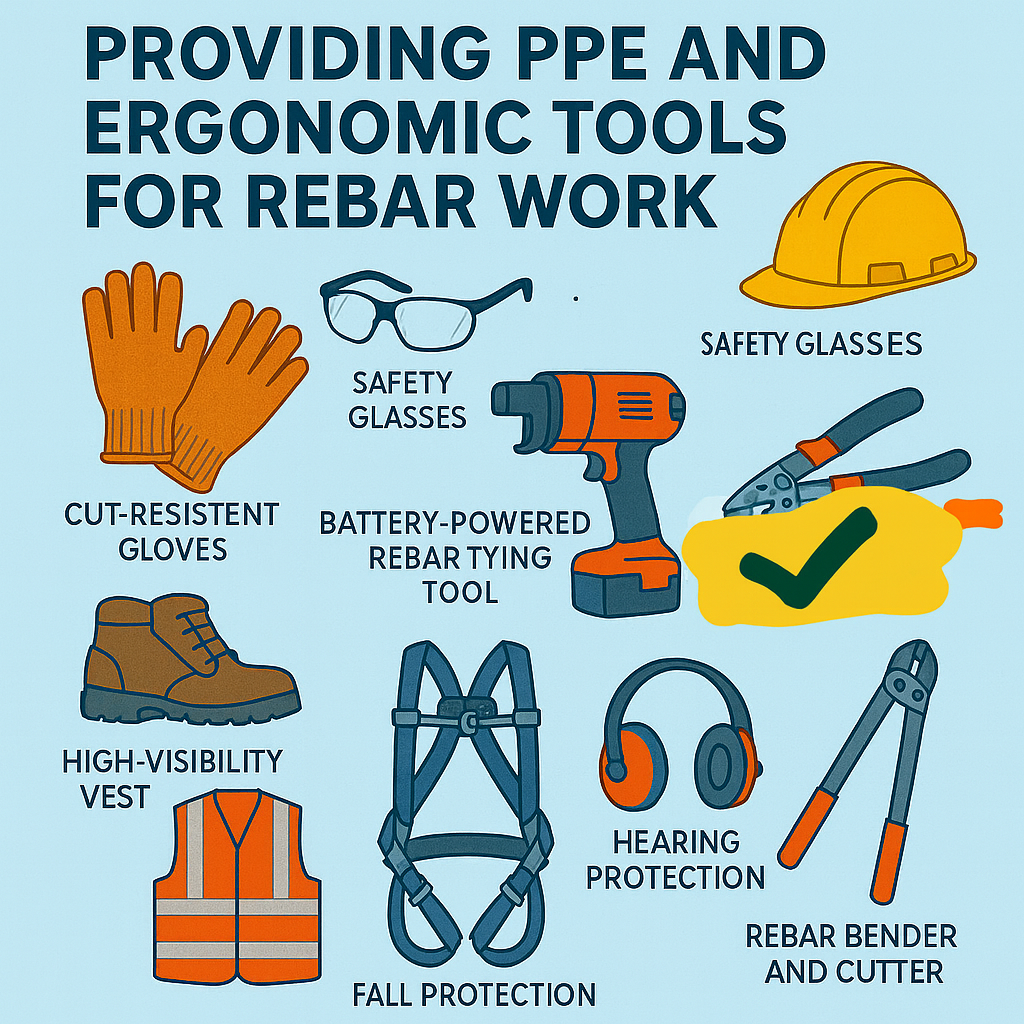

Workers should use cut-resistant gloves that balance protection with flexibility. Gloves reduce cuts while still allowing dexterity for tying tasks.

2. Rotate Tasks to Reduce Repetition

Assigning workers to different duties (tying, cutting, moving rebar) helps prevent repetitive strain. Task rotation is a proven way to reduce musculoskeletal injuries, according to NIOSH.

3. Use Ergonomic Tying Tools

Newer battery-powered rebar tying guns reduce strain by eliminating repetitive twisting motions. Where manual tying is necessary, ergonomically designed pliers lower wrist stress.

4. Train Workers in Proper Technique

Simple adjustments—such as changing hand positions, standing posture, or using both hands—reduce repetitive stress. Supervisors should include ergonomics in toolbox talks.

5. Schedule Regular Breaks

Frequent micro-breaks give muscles and tendons time to recover. Even a 2-minute stretch every 30 minutes can reduce fatigue in the hands and wrists.

6. Implement Warm-Up and Stretch Programs

Construction companies can adopt short hand and wrist warm-up routines before shifts. Stretching improves blood flow and lowers the risk of strains.

7. Maintain Tools and Equipment

Worn-out pliers and cutters require more force, increasing strain. Keeping tools sharp and in good condition makes tying faster and safer.

8. Encourage Early Reporting of Pain

Workers often ignore early symptoms of tendonitis or carpal tunnel. Encouraging reporting and providing early treatment helps prevent long-term disability.

Case Example: Lessons from the Jobsite

A Canadian bridge contractor noticed high injury rates among rebar workers.

After introducing battery-powered tying tools, mandatory gloves, and task rotation, hand and wrist injuries dropped by 40% within a year. This case reinforces the importance of combining technology and training to protect workers.

Role of Employers and Supervisors

Employers play a crucial role in preventing hand and wrist injuries in rebar work by:

- Providing PPE and ergonomic tools.

- Creating policies that limit repetitive strain.

- Conducting regular OHSE training.

- Auditing worksites to ensure safety practices are followed.

Supervisors should lead by example, reminding workers to rotate tasks and report discomfort.

Conclusion

Rebar work is tough, demanding, and essential. But it doesn’t have to come at the cost of workers’ health. By focusing on ergonomics, PPE, training, and early intervention, employers can significantly reduce the risk of hand and wrist injuries in rebar work.

Protecting the hands that tie the steel is more than a safety measure—it’s an investment in the people who build our bridges, towers, and cities. For more occupational safety guidance, visit OHSE.ca.

No comments yet