Winter safety becomes a critical concern as temperatures drop, snow and ice accumulate, and daylight hours shorten. Occupational Health, Safety, and Environment (OHSE) professionals recognize that winter brings an elevated risk of slips, falls, cold-related illnesses, and equipment malfunctions.

Understanding and mitigating these hazards are vital for maintaining a safe, productive work environment across industries.

From construction and healthcare to transportation and manufacturing, winter safety measures protect workers, minimize downtime, and reinforce a strong safety culture.

This article explores essential OHSE practices, training priorities, and environmental strategies that ensure your workplace remains safe even in the harshest conditions.

- Understanding Common Winter Safety Hazards

- Implementing OHSE Controls for Winter Safety

- Vehicle and Fleet Winter Safety

- Cold Stress Prevention and Worker Health

- Indoor Workplace Safety in Winter

- Emergency Preparedness and Response Plans

- Building a Culture of Winter Safety

- Leveraging Technology for Winter Safety

- Conclusion: Winter Safety as a Year-Round Priority

Understanding Common Winter Safety Hazards

Cold weather introduces a unique combination of hazards that can compromise worker safety if not properly addressed. These include:

- Slips, Trips, and Falls: Ice, snow, and slush on walkways and parking lots increase the likelihood of slips and injuries. Employers must ensure timely snow removal and the use of non-slip mats.

- Cold Stress and Frostbite: Workers exposed to freezing conditions may suffer hypothermia, frostbite, or trench foot. Continuous exposure to wet clothing accelerates these risks.

- Reduced Visibility: Shorter days and poor lighting make it harder for drivers and pedestrians to see each other, increasing accident risks.

- Vehicle and Equipment Failures: Cold temperatures can cause engines to seize, batteries to fail, or brakes to malfunction.

- Indoor Air Quality Issues: Overuse of heating systems can lead to dry air, poor ventilation, and discomfort, impacting worker productivity and health.

For detailed hazard prevention guidance, resources from the Canadian Centre for Occupational Health and Safety (CCOHS) and OHSE.ca provide comprehensive winter safety checklists.

Implementing OHSE Controls for Winter Safety

Effective OHSE management focuses on three primary control strategies: engineering controls, administrative controls, and personal protective equipment (PPE).

Engineering Controls

- Install heated entry mats and proper drainage systems to prevent pooling water.

- Use canopies or shelters at outdoor workstations to block wind and precipitation.

- Improve lighting systems in parking lots, walkways, and loading docks.

Administrative Controls

- Introduce winter-specific safety training focusing on hazard recognition, emergency response, and proper PPE use.

- Adjust work schedules to reduce outdoor exposure during extreme cold.

- Encourage “buddy systems” so employees can monitor each other for signs of cold stress.

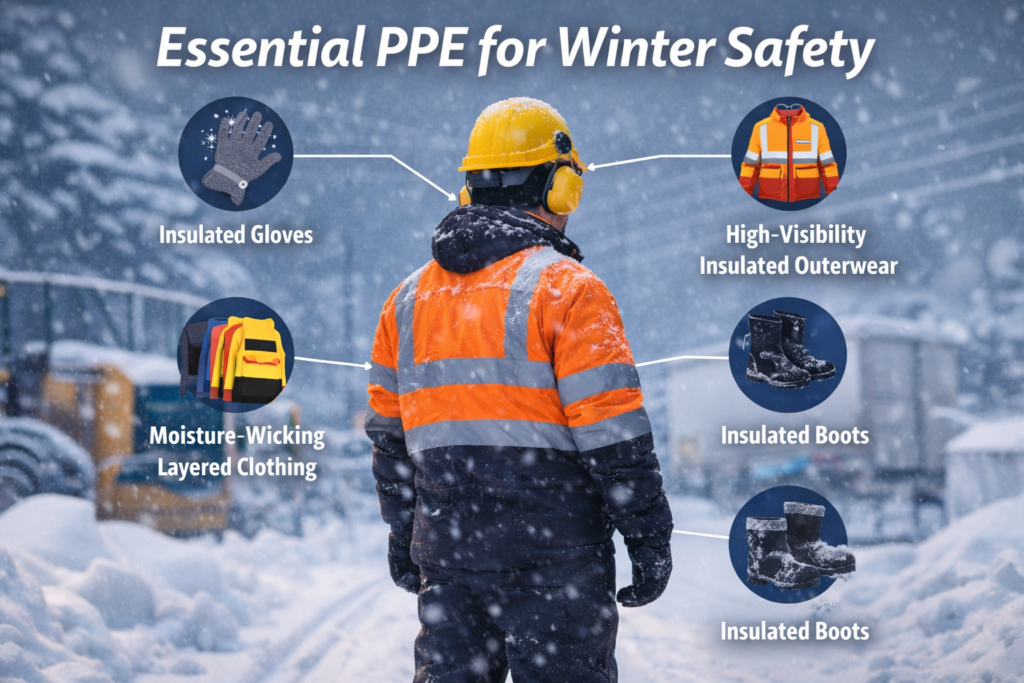

Personal Protective Equipment (PPE)

- Provide insulated gloves, boots, and head protection suited for sub-zero conditions.

- Ensure workers wear layered, moisture-wicking clothing that maintains warmth while allowing movement.

- Mandate high-visibility vests or jackets during low-light hours to prevent vehicular accidents.

Vehicle and Fleet Winter Safety

Transportation and logistics teams face major challenges during winter. OHSE best practices require all company vehicles to undergo thorough inspections before the season begins.

- Check tire tread depth, battery strength, and brake function regularly.

- Keep emergency kits with blankets, flashlights, jumper cables, and first-aid supplies in every vehicle.

- Train drivers to recognize black ice and maintain safe braking distances.

- Limit travel during snowstorms or blizzards, aligning with local weather advisories such as those issued by Environment and Climate Change Canada.

Proper vehicle maintenance not only ensures safety but also supports environmental goals by reducing emissions from inefficient engines.

Cold Stress Prevention and Worker Health

OHSE professionals emphasize proactive measures to protect workers from cold-related illnesses. According to the Centers for Disease Control and Prevention (CDC), early intervention can save lives and prevent long-term injury.

Key prevention measures include:

- Scheduling warm-up breaks in heated shelters.

- Providing warm beverages and adequate hydration.

- Monitoring wind chill and air temperature using workplace thermometers.

- Ensuring supervisors are trained to identify early signs of hypothermia or frostbite.

Encouraging workers to report discomfort early reinforces a safety-first mindset and helps maintain compliance with OHSE regulations.

Indoor Workplace Safety in Winter

While outdoor workers face cold-related hazards, indoor environments also present seasonal risks. Wet floors near entrances, overloaded electrical outlets for heaters, and poor air circulation are common.

Employers should:

- Use absorbent mats at all entrances to prevent slippery surfaces.

- Regularly inspect HVAC systems to ensure proper air quality.

- Avoid using space heaters without automatic shut-offs or certification labels.

These preventive steps reduce fire hazards and maintain indoor comfort throughout the season.

Emergency Preparedness and Response Plans

Every workplace should maintain a winter emergency preparedness plan that aligns with OHSE standards. This plan should outline:

- Emergency contact procedures.

- Evacuation routes during snowstorms or power outages.

- Communication systems for remote or isolated workers.

- Designated warming stations or emergency shelters.

Workplaces can reference Public Safety Canada’s emergency management guidelines for model frameworks.

Building a Culture of Winter Safety

Safety culture is not built overnight—it evolves through leadership, employee engagement, and continuous improvement. Managers must lead by example, consistently wearing proper PPE and enforcing safety practices.

Encourage open communication where workers can report hazards without fear of retaliation. Incorporate toolbox talks, digital OHSE newsletters, or safety posters highlighting winter safety reminders. A simple reminder like “Three Points of Contact on Icy Steps” can significantly reduce fall incidents.

Integrating winter safety into everyday operations demonstrates commitment not only to compliance but also to genuine worker well-being.

Leveraging Technology for Winter Safety

Modern OHSE systems use smart technologies to enhance monitoring and communication:

- IoT sensors track temperature and humidity levels in real-time.

- Wearable devices detect worker fatigue or body temperature changes.

- Mobile OHSE apps help report hazards instantly and verify corrective actions.

Digital platforms like OHSE.ca offer online training, inspection templates, and analytics tools that simplify seasonal safety management.

Conclusion: Winter Safety as a Year-Round Priority

Winter safety should never be an afterthought. By embedding OHSE principles into every level of your organization—from management planning to worker behavior—you ensure safety, productivity, and compliance even during Canada’s harshest months.

Employers who champion proactive winter safety programs not only prevent injuries but also cultivate a resilient workforce prepared for any environmental challenge. Let’s make this winter a season of preparedness, awareness, and zero incidents.

SEO Title: Winter Safety: Proven OHSE Strategies for a Safer Workplace This Winter

Meta Description: Stay safe this winter with essential OHSE winter safety tips. Learn how to prevent slips, cold stress, and equipment failures using effective workplace safety strategies.

Focus Keyword: winter safety

No comments yet