Common Workplace Hazards Employers Often Overlook continue to put workers, businesses, and reputations at risk despite existing safety programs and compliance efforts.

Many organizations focus heavily on obvious dangers such as heavy machinery, working at heights, or hazardous chemicals. While these are critical, some of the most damaging risks are hidden in plain sight—quietly increasing injury rates, absenteeism, and long-term costs.

Common Workplace Hazards Employers Often Overlook are often normalized as “part of the job,” which makes them even more dangerous. Addressing these overlooked risks is not just a regulatory obligation; it is a strategic decision that protects people, productivity, and brand credibility.

- Common Workplace Hazards Employers Often Overlook: Poor Ergonomics

- Common Workplace Hazards Employers Often Overlook: Psychosocial Risks

- Common Workplace Hazards Employers Often Overlook: Slips, Trips, and Falls

- Common Workplace Hazards Employers Often Overlook: Fatigue and Shift Work

- Common Workplace Hazards Employers Often Overlook: Inadequate Training and Competency Gaps

- Common Workplace Hazards Employers Often Overlook: Poor Maintenance and Aging Equipment

- Common Workplace Hazards Employers Often Overlook: Chemical Exposure at Low Levels

- Common Workplace Hazards Employers Often Overlook: Emergency Preparedness Gaps

- Common Workplace Hazards Employers Often Overlook: Contractor and Visitor Safety

- Why Addressing Common Workplace Hazards Employers Often Overlook Matters

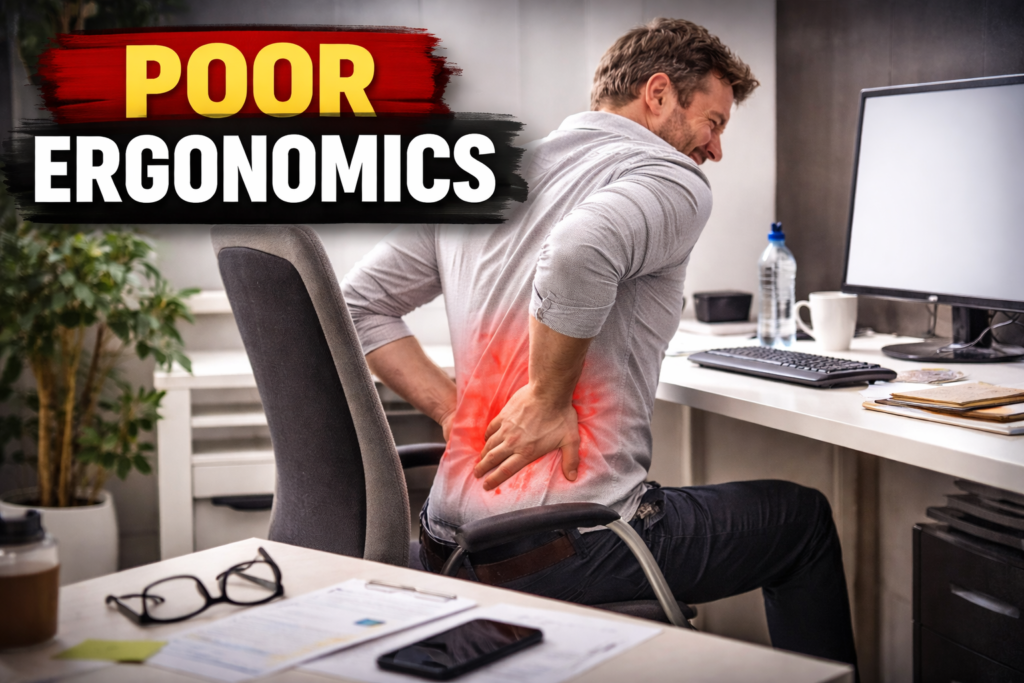

Common Workplace Hazards Employers Often Overlook: Poor Ergonomics

Common Workplace Hazards Employers Often Overlook frequently include ergonomic risks, especially in offices, healthcare settings, warehouses, and remote work environments.

Poorly adjusted chairs, monitors placed at incorrect heights, repetitive motions, and awkward postures slowly strain the musculoskeletal system. Unlike acute injuries, ergonomic injuries develop gradually, which makes them easy to dismiss until they result in chronic pain or long-term disability claims.

When employers underestimate ergonomics, they often see rising cases of back pain, carpal tunnel syndrome, shoulder injuries, and neck strain. According to guidance from organizations like the Canadian Centre for Occupational Health and Safety, proactive ergonomic assessments significantly reduce lost-time injuries.

Investing in adjustable furniture, task variation, and ergonomic training delivers measurable returns in productivity and morale. Employers who overlook this risk pay the price through presenteeism and compensation costs.

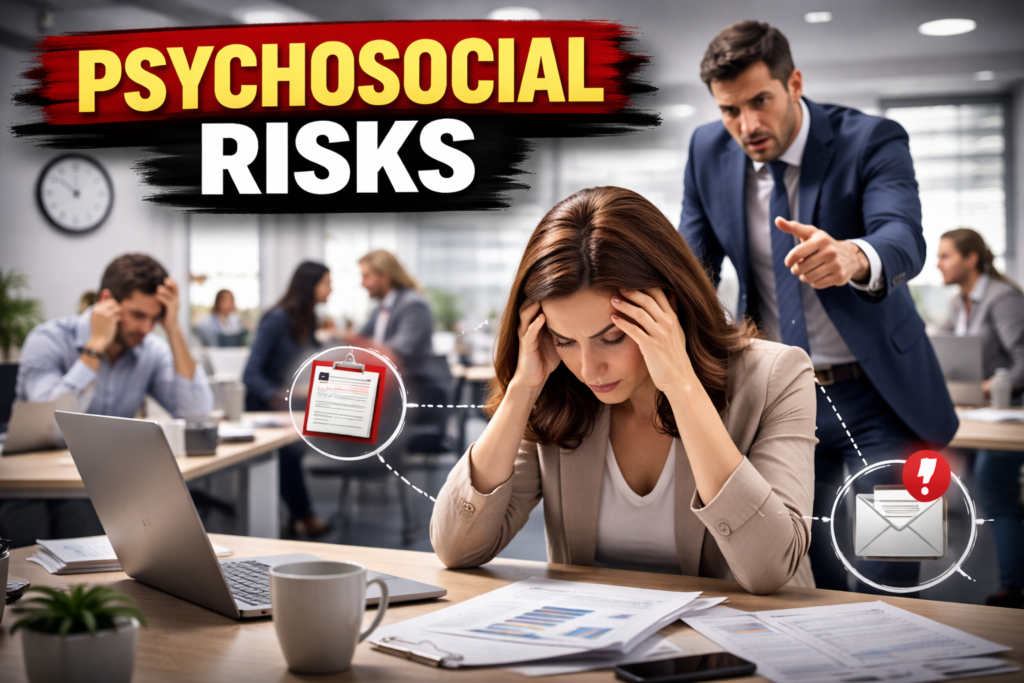

Common Workplace Hazards Employers Often Overlook: Psychosocial Risks

Common Workplace Hazards Employers Often Overlook are not always physical. Psychosocial hazards such as excessive workloads, unclear job roles, workplace harassment, and lack of support are among the fastest-growing safety concerns.

These hazards directly contribute to stress, burnout, anxiety, and depression, all of which affect job performance and retention.

When psychosocial risks are ignored, organizations experience higher turnover, more sick days, and increased conflict.

Canadian employers are increasingly expected to align with the National Standard of Canada for Psychological Health and Safety in the Workplace. Addressing these hazards through supportive leadership, realistic workloads, and open communication creates healthier teams and reduces long-term business risk.

Common Workplace Hazards Employers Often Overlook: Slips, Trips, and Falls

Common Workplace Hazards Employers Often Overlook include slips, trips, and falls because they appear minor or unavoidable. In reality, these incidents remain one of the leading causes of workplace injuries across industries.

Wet floors, uneven surfaces, trailing cables, poor lighting, and cluttered walkways are often overlooked during routine operations.

These hazards persist because they blend into daily routines. A single slip can lead to fractures, sprains, or head injuries, resulting in significant downtime.

Regular housekeeping inspections, proper signage, non-slip flooring, and employee awareness campaigns are simple yet effective controls. Employers who treat these hazards seriously demonstrate a strong safety culture and reduce preventable injuries.

Common Workplace Hazards Employers Often Overlook: Fatigue and Shift Work

Common Workplace Hazards Employers Often Overlook become especially dangerous in environments that rely on extended shifts, overtime, or night work. Fatigue impairs judgment, slows reaction times, and increases the likelihood of errors and accidents. This risk is common in healthcare, transportation, manufacturing, and emergency services.

Fatigue-related incidents often go unreported because workers feel pressure to “push through.” Employers must recognize fatigue as a legitimate safety hazard, not a personal weakness.

Implementing fatigue management programs, reasonable scheduling, adequate rest breaks, and education on sleep hygiene can dramatically reduce incidents. Resources from groups such as WorkSafeBC highlight fatigue as a critical but manageable risk.

Common Workplace Hazards Employers Often Overlook: Inadequate Training and Competency Gaps

Common Workplace Hazards Employers Often Overlook are often rooted in assumptions about worker competency.

Employers may assume that experienced workers no longer need refresher training or that new hires will “learn on the job.” This mindset creates gaps in knowledge, especially when procedures, equipment, or regulations change.

Insufficient training increases the risk of unsafe shortcuts, improper equipment use, and inconsistent safety practices. Regular refresher training, clear standard operating procedures, and competency verification are essential.

Platforms like OHSE.ca emphasize that training should be continuous, practical, and relevant to real-world tasks rather than a one-time checkbox exercise.

Common Workplace Hazards Employers Often Overlook: Poor Maintenance and Aging Equipment

Common Workplace Hazards Employers Often Overlook include deteriorating equipment and deferred maintenance. Worn-out tools, faulty guards, leaking systems, and outdated infrastructure increase the likelihood of mechanical failures and injuries. These risks are often normalized until a serious incident occurs.

Preventive maintenance programs are critical for identifying hazards before they escalate. Employers should encourage workers to report equipment issues without fear of blame.

Regular inspections, maintenance logs, and timely repairs reduce downtime and demonstrate a commitment to safety. Ignoring maintenance hazards often leads to higher repair costs and regulatory scrutiny after incidents occur.

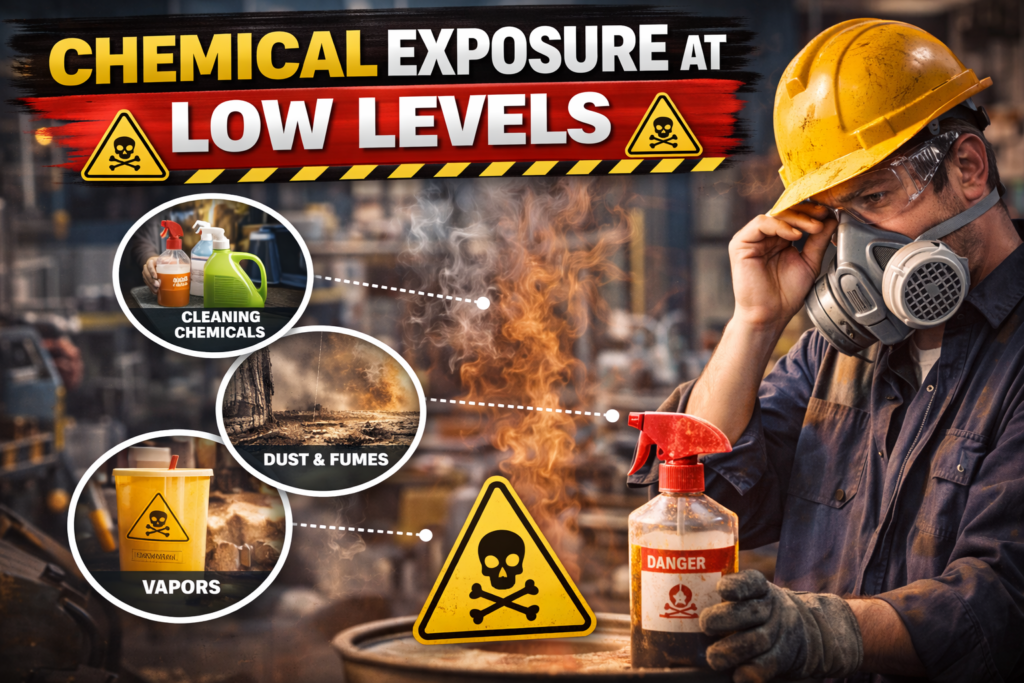

Common Workplace Hazards Employers Often Overlook: Chemical Exposure at Low Levels

Common Workplace Hazards Employers Often Overlook are not limited to obvious chemical spills or toxic releases. Low-level, long-term exposure to cleaning agents, fumes, dust, and vapors can cause serious health effects over time. Workers may not recognize these exposures as hazardous because symptoms develop slowly.

Employers must ensure proper labeling, ventilation, safe storage, and training aligned with WHMIS requirements.

Even common substances can pose risks if controls are inadequate. Reliable information from sources such as the Canadian Centre for Occupational Health and Safety supports employers in managing chemical risks responsibly and proactively.

Common Workplace Hazards Employers Often Overlook: Emergency Preparedness Gaps

Common Workplace Hazards Employers Often Overlook become critical during emergencies. Inadequate emergency plans, outdated evacuation maps, untrained fire wardens, or blocked exits can turn manageable incidents into disasters. Many organizations have plans on paper but fail to practice them regularly.

Regular drills, updated emergency procedures, and clear communication ensure workers know how to respond under pressure.

Emergency preparedness should evolve with changes in staffing, layout, or operations. Employers who invest in preparedness protect lives and minimize chaos during unexpected events.

Common Workplace Hazards Employers Often Overlook: Contractor and Visitor Safety

Common Workplace Hazards Employers Often Overlook extend beyond direct employees. Contractors, temporary workers, and visitors often face higher risks due to unfamiliarity with the site. Assuming they will manage their own safety can lead to serious incidents and shared liability.

Clear orientation, site-specific safety rules, supervision, and communication are essential. Employers remain responsible for ensuring a safe environment for everyone on site.

Overlooking this responsibility exposes organizations to legal, financial, and reputational damage.

Why Addressing Common Workplace Hazards Employers Often Overlook Matters

Common Workplace Hazards Employers Often Overlook directly impact injury rates, insurance premiums, employee engagement, and organizational reputation.

Proactively identifying and controlling these risks strengthens safety culture and demonstrates leadership commitment. More importantly, it protects workers from preventable harm and supports sustainable business performance.

Addressing overlooked hazards does not require complex solutions. It starts with awareness, worker involvement, regular inspections, and continuous improvement.

Employers who prioritize these hidden risks position themselves as responsible, resilient, and forward-thinking organizations.

No comments yet