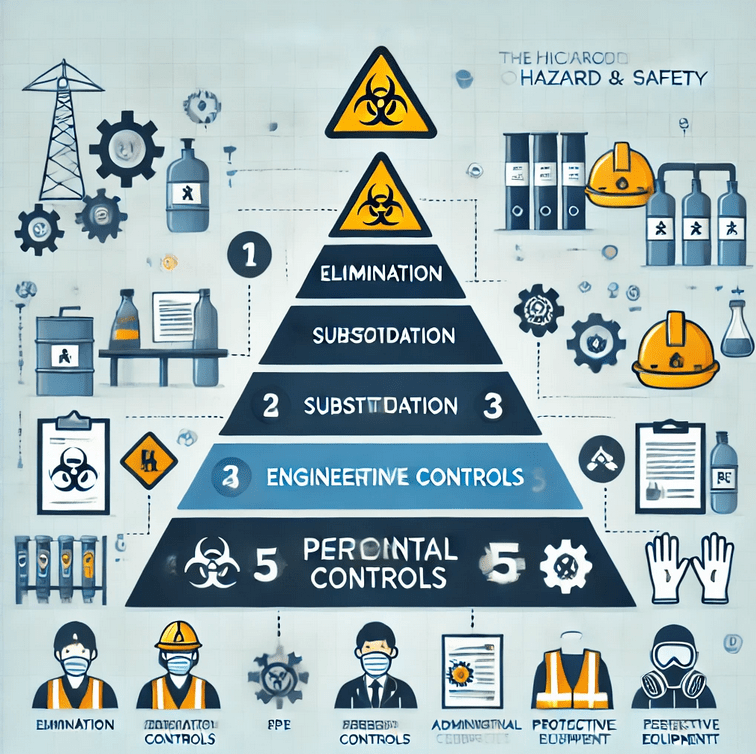

Effective hazard control is crucial for ensuring workplace safety and protecting employees from potential risks. The hierarchy of hazard control is a structured approach used by occupational health and safety professionals to minimize or eliminate exposure to hazards.

This article provides an in-depth exploration of each level in the hierarchy, complete with notes and illustrative tables to guide practical application.

1. Elimination

Elimination is the most effective method of hazard control. It involves physically removing the hazard from the workplace, thereby reducing the risk to zero.

Example: Removing a chemical process that produces harmful emissions and substituting it with a safer process.

Notes:

- Challenges: Complete removal may not always be feasible due to operational constraints.

- Benefits: Offers permanent risk reduction and is highly effective when applicable.

Table 1: Elimination Pros and Cons

| Pros | Cons |

|---|---|

| Permanent risk reduction | May be costly or complex |

| No need for ongoing PPE | Not feasible for all risks |

| Simplifies training needs | Can disrupt workflow |

2. Substitution

Substitution involves replacing a hazardous substance or process with a less hazardous one. Although it is a step below elimination, substitution can significantly reduce risks.

Example: Using non-toxic cleaning agents instead of harmful chemicals.

Notes:

- Considerations: Evaluate potential risks that may arise from the substitute.

- Practical Tip: Conduct thorough risk assessments before making a change.

Table 2: Substitution Effectiveness

| Substitution Type | Risk Reduction Level |

|---|---|

| Toxic substance to non-toxic | High |

| High-noise equipment to low-noise | Medium |

| Manual lifting to automated lift | High |

3. Engineering Controls

Engineering controls are physical changes to the workplace that reduce exposure to hazards. These can be highly effective as they create a barrier between the worker and the hazard.

Examples: Installing ventilation systems, enclosing machinery, or adding safety guards.

Notes:

- Pros: Does not rely on employee behavior.

- Cons: Often requires upfront investment and maintenance.

Table 3: Common Engineering Controls

| Engineering Control | Example | Risk Reduced |

|---|---|---|

| Ventilation systems | Fume hoods in labs | Airborne contaminants |

| Machine guards | Safety guards on saws | Physical injuries |

| Enclosures | Isolating noisy equipment | Noise exposure |

4. Administrative Controls

Administrative controls involve changes to work policies or procedures to reduce risk. These controls do not remove the hazard but limit exposure.

Examples: Implementing job rotation schedules, safety training, and standard operating procedures (SOPs).

Notes:

- Drawback: Effectiveness depends on consistent enforcement and worker compliance.

- Complementary Measures: Often used alongside engineering controls and PPE.

Table 4: Administrative Controls Implementation

| Administrative Control | Description | Effectiveness |

|---|---|---|

| Job rotation | Rotating workers to limit exposure time | Moderate |

| Safety training | Educating workers on safe practices | High if adhered to |

| SOPs | Step-by-step task procedures | Medium |

5. Personal Protective Equipment (PPE)

PPE is considered the last line of defense. While it is essential in many situations, it is the least effective form of control because it relies on the correct and consistent use by employees.

Examples: Gloves, safety goggles, face masks, ear protection.

Notes:

- Limitations: Does not eliminate the hazard; only reduces exposure.

- Challenges: Ensuring proper usage, maintaining supply, and training.

Table 5: PPE Effectiveness

| PPE Type | Protection Level | Limitations |

|---|---|---|

| Respirators | High for airborne particles | Limited by fit and usage |

| Safety goggles | Protects eyes from splashes | Does not cover full face |

| Gloves | Protects hands from chemicals | May not be chemical-proof |

| Earplugs | Reduces noise exposure | Ineffective if not worn properly |

Summary and Best Practices

The hierarchy of hazard control should be applied sequentially, starting from elimination down to PPE. Combining multiple levels often yields the best results. For instance, engineering controls paired with PPE provide a more robust defense than either measure alone.

Key Takeaway: Always prioritize hazard controls that do not rely solely on human behavior, and ensure ongoing training and compliance checks to maximize effectiveness.

No comments yet