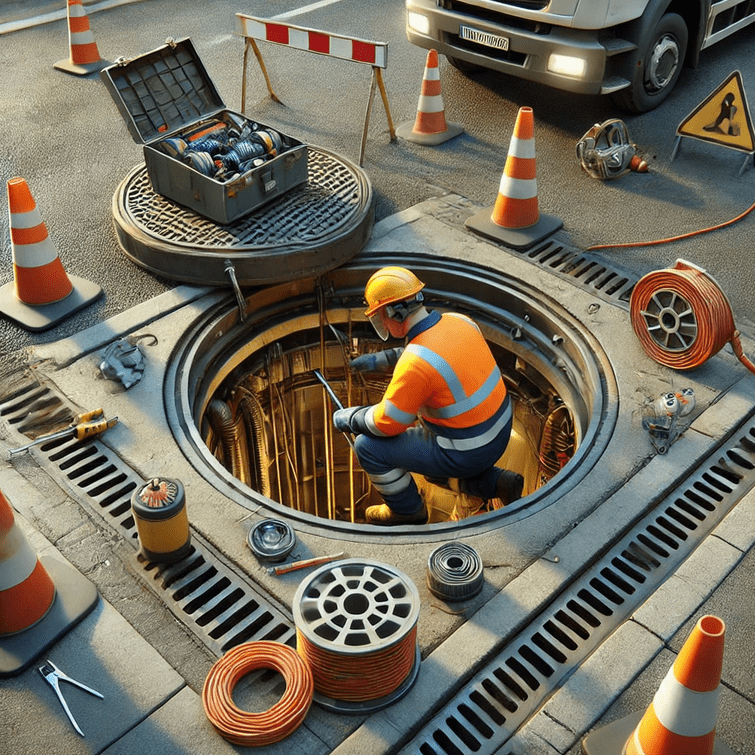

Manholes are critical access points to various underground infrastructure systems, such as sewer, electrical, and telecommunications systems. These confined spaces are often areas of heightened risk, where occupational health and safety measures must be strictly adhered to.

Working in and around manholes involves multiple hazards such as falls, toxic gases, electrocution, and engulfment. This article will detail the essential OHSE practices for manhole operations, including a detailed safety checklist, risk assessment, and mitigation strategies.

- 1. Introduction

- 2. Manhole Hazards

- 3. Risk Assessment and Hazard Control

- 4. Personal Protective Equipment (PPE) for Manhole Operations

- 5. Confined Space Entry Procedures

- 6. Rescue Plan and Emergency Procedures

- 7. Training Requirements

- 8. Conclusion

- 9. FAQ and Key Questions

- Manhole Safety Quiz

- Additional Notes:

1. Introduction

Manhole work is classified under confined space entry, which requires special attention due to the restricted nature of the environment and the variety of hazards that may exist. Due to its limited entry and exit points, poor ventilation, and the potential presence of hazardous substances, manhole operations require stringent safety protocols to ensure worker safety.

The aim of this article is to provide a comprehensive understanding of the hazards involved and the occupational health and safety standards required to work safely in and around manholes.

2. Manhole Hazards

2.1. Physical Hazards:

- Falls: Workers can fall into an open manhole during entry or exit, resulting in injury.

- Falling objects: Tools or debris may fall from ground level into the manhole.

- Slips and Trips: Slippery surfaces due to water, grease, or other substances.

2.2. Atmospheric Hazards:

- Toxic Gases: Hydrogen sulfide (H₂S), methane (CH₄), and carbon monoxide (CO) are common toxic gases found in sewer manholes.

- Oxygen Deficiency: Lack of oxygen due to displacement by other gases, or poor ventilation, can cause suffocation.

- Explosive Atmosphere: Presence of flammable gases can lead to explosions if not monitored properly.

2.3. Electrical Hazards:

- Electrocution: Exposure to live electrical cables or equipment within electrical manholes.

2.4. Biological Hazards:

- Exposure to pathogens: Manholes connected to sewer systems may expose workers to harmful biological agents such as bacteria, viruses, or molds.

3. Risk Assessment and Hazard Control

Before starting any manhole work, it is critical to conduct a thorough risk assessment to identify hazards and implement controls. Below is a step-by-step guide to assessing risks in manhole operations.

| Risk Type | Possible Hazards | Control Measures |

|---|---|---|

| Physical | Falls, slips, trips | Use safety harnesses, provide guardrails, ensure clear access points. |

| Atmospheric | Toxic gases, oxygen deficiency | Perform gas testing before entry, ensure adequate ventilation, use portable air monitors. |

| Electrical | Live wires, high voltage | Isolate power sources, use insulated tools, follow lockout/tagout procedures. |

| Biological | Pathogens from sewage | Use proper PPE, including gloves and respirators, ensure good hygiene practices. |

4. Personal Protective Equipment (PPE) for Manhole Operations

The right PPE is crucial for protecting workers from the hazards associated with manhole work. The following equipment is typically required:

- Hard Hat: Protects from falling objects or head injuries.

- Respirator: For protection against toxic gases or insufficient oxygen levels.

- Full-Body Harness and Lifeline: Essential for fall prevention and rescue operations.

- Gas Monitor: For constant atmospheric monitoring to detect hazardous gases.

- Safety Boots and Gloves: Prevent injuries from sharp objects, contamination, or burns.

- Chemical-Resistant Clothing: When dealing with hazardous liquids or sewage.

| PPE Item | Purpose |

|---|---|

| Hard Hat | Protects from falling objects. |

| Respirator (if needed) | Protects from inhaling toxic gases. |

| Safety Harness | Prevents falls inside the manhole. |

| Gas Detector | Monitors for toxic gases or low oxygen. |

| Gloves and Safety Boots | Protection from sharp objects or contaminants. |

5. Confined Space Entry Procedures

Confined spaces, such as manholes, require specific entry procedures to ensure worker safety. Employers must have a comprehensive confined space entry program, which includes:

- Permit-to-Work System: Before any entry, a permit must be issued and signed by a qualified person verifying the space is safe for work.

- Atmospheric Testing: Testing the air inside the manhole for toxic gases and oxygen levels before and during work.

- Ventilation: Mechanical or natural ventilation should be provided to maintain breathable air levels.

- Communication System: Ensure reliable communication between the worker inside the manhole and those outside.

- Standby Attendant: An attendant should always be present outside the manhole in case of an emergency.

6. Rescue Plan and Emergency Procedures

One of the most critical aspects of manhole work is having a rescue plan in place. Emergency rescue operations in confined spaces can be complex, and time is of the essence. A well-prepared rescue plan includes:

- Rescue Equipment: Equipment such as a tripod and winch system must be available and tested before work begins.

- Rescue Team Training: Ensure that the rescue team is trained in confined space rescue procedures.

- Communication Devices: Use communication devices like radios to maintain constant contact with workers inside.

- Emergency Evacuation Plan: Establish clear evacuation routes and emergency medical services (EMS) contacts.

7. Training Requirements

Workers involved in manhole operations must undergo comprehensive training on the following topics:

- Confined space entry and exit protocols.

- Atmospheric testing and gas detection.

- Proper use of PPE and rescue equipment.

- First aid and CPR training for confined space emergencies.

- Lockout/tagout procedures for electrical manholes.

8. Conclusion

Manhole operations involve multiple hazards that require detailed attention to safety. Employers must ensure that workers are adequately trained, PPE is provided, and confined space entry procedures are followed. By maintaining stringent safety standards, the risks associated with manhole work can be significantly reduced.

9. FAQ and Key Questions

- What are the common gases found in sewer manholes?

- Hydrogen sulfide (H₂S), methane (CH₄), and carbon monoxide (CO) are common toxic gases found in sewer manholes.

- What is the purpose of a confined space entry permit?

- A confined space entry permit ensures that the manhole is safe for entry after a thorough risk assessment and atmospheric testing.

- What kind of PPE is essential for manhole work?

- Essential PPE includes a hard hat, respirator, full-body harness, gas monitor, safety boots, and gloves.

- Why is atmospheric testing important before entering a manhole?

- Atmospheric testing checks for toxic gases and oxygen levels to ensure a safe working environment.

Manhole Safety Quiz

- Which gas is commonly found in manholes and poses a serious risk of explosion?

- A) Oxygen

- B) Carbon Dioxide

- C) Methane

- D) Nitrogen

- What is the first step in entering a manhole?

- A) Start work immediately

- B) Conduct atmospheric testing

- C) Remove the manhole cover

- D) Put on a hard hat

- Which of the following is NOT a type of PPE required for manhole entry?

- A) Full-body harness

- B) Gas monitor

- C) Insulated safety gloves

- D) Hearing protection

Additional Notes:

- Regular safety audits and drills should be conducted to ensure compliance with safety procedures.

- Workers should never enter a manhole alone; there must always be a standby attendant.

- Proper signage and barricades must be placed around open manholes to prevent public accidents.

No comments yet