Trenching and excavation are common tasks in construction, utility work, and landscaping, but they come with significant risks. Working in and around trenches poses dangers like cave-ins, falls, hazardous atmospheres, and equipment accidents.

Due to these hazards, it is essential to follow strict safety measures to protect workers and maintain compliance with Occupational Health and Safety (OHS) regulations.

This article covers essential tips and best practices for trenching and excavation safety, helping to ensure a secure work environment for all involved.

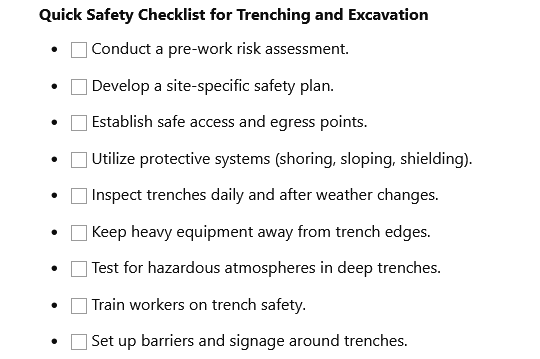

- 1. Conduct a Pre-Work Risk Assessment

- 2. Create a Site Safety Plan

- 3. Establish Safe Access and Egress

- 4. Utilize Protective Systems

- 5. Inspect Trenches Daily

- 6. Keep Heavy Equipment Away from Edges

- 7. Monitor Hazardous Atmospheres

- 8. Manage Water Accumulation

- 9. Train Workers on Trench Safety

- 10. Set Up Barrier Protection and Signage

Understanding the Risks of Trenching and Excavation

Trenches and excavations are inherently hazardous, with cave-ins being the leading cause of fatalities. Other risks include:

- Cave-ins: The most common hazard, which occurs when the walls of a trench collapse.

- Falls and Falling Loads: Workers can fall into trenches, or equipment and materials can fall onto workers below.

- Hazardous Atmospheres: Toxic gases, low oxygen levels, or combustible atmospheres can accumulate in trenches.

- Equipment Hazards: Heavy machinery like backhoes and excavators increase the risk of injury if not operated safely.

- Water Accumulation: Rain or groundwater can lead to flooding, making the trench unstable.

Essential Trenching and Excavation Safety Tips

To mitigate these risks, here are some essential safety tips for trenching and excavation work:

1. Conduct a Pre-Work Risk Assessment

Before starting any trenching or excavation work, conduct a thorough risk assessment to identify potential hazards. This includes analyzing soil type, assessing the presence of underground utilities, and evaluating environmental conditions. The risk assessment helps plan the safest approach and identify any equipment or support systems needed.

2. Create a Site Safety Plan

A comprehensive safety plan tailored to the specific project is essential. It should cover:

- Protective Systems: Methods like shoring, sloping, or shielding to prevent cave-ins.

- Emergency Procedures: Clear guidelines on how to respond in case of an accident or hazard.

- Roles and Responsibilities: Assign tasks and responsibilities, ensuring everyone understands their duties.

Having a well-defined plan helps ensure that everyone knows their role in maintaining a safe environment.

3. Establish Safe Access and Egress

Trenches deeper than four feet require safe entry and exit points, such as ladders, ramps, or steps. Ensure that workers have easy access to egress points within 25 feet of their location at all times. This measure helps workers quickly escape in case of an emergency.

4. Utilize Protective Systems

Protective systems are essential for preventing cave-ins and keeping trenches stable. The main types of protective systems are:

- Shoring: A support system that uses hydraulic jacks or metal braces to hold trench walls in place.

- Sloping: Cutting back the trench wall at an angle to prevent collapse.

- Shielding: Using trench boxes or similar devices to protect workers from cave-ins.

Always select the protective system based on the soil type, trench depth, and width.

5. Inspect Trenches Daily

A competent person should inspect trenches at the beginning of each shift, after rain, or whenever conditions change. Inspections help identify any signs of instability, water accumulation, or hazardous atmospheres. Promptly address any issues to ensure the trench remains safe for entry.

Table: Common Trench Inspection Criteria

| Inspection Criterion | Description |

|---|---|

| Wall Stability | Look for cracks or signs of sloughing or shifting walls. |

| Water Accumulation | Check for water buildup that could destabilize the trench. |

| Soil Condition | Evaluate soil to ensure it remains compact and stable. |

| Equipment Positioning | Ensure machinery is positioned safely from trench edges. |

| Atmospheric Testing | Test for toxic gases or oxygen levels in deep trenches. |

6. Keep Heavy Equipment Away from Edges

Heavy equipment like excavators or trucks can exert pressure on trench walls, increasing the risk of a collapse. Keep all equipment and materials at least two feet away from the edge of the trench. This distance reduces the likelihood of cave-ins and falling objects.

7. Monitor Hazardous Atmospheres

In deeper trenches, hazardous atmospheres may arise due to limited ventilation. Testing for low oxygen levels, toxic gases, and flammable vapors is essential, especially in trenches deeper than four feet. Use gas detection equipment and ventilate the area as necessary to maintain safe working conditions.

8. Manage Water Accumulation

Trenches can quickly accumulate water due to rain or groundwater seepage. Implement drainage systems or pumps to remove water as it accumulates. If water starts to compromise trench stability, workers should evacuate the trench until it is stabilized.

9. Train Workers on Trench Safety

All workers should undergo trench safety training before entering an excavation site. Training should cover:

- Recognizing potential hazards

- Proper use of protective systems

- Emergency response procedures

- Safe equipment handling practices

Regular training sessions reinforce safety practices and ensure workers stay informed about potential risks and safe procedures.

10. Set Up Barrier Protection and Signage

Install barriers, cones, or fencing around the trench to prevent unauthorized entry and protect workers from falling. Proper signage warning of open trenches, deep excavations, and machinery operation helps inform passersby and workers of the hazards present.

Additional Safety Considerations

- Assign a Competent Person: Ensure a qualified individual, trained in trench safety, is on-site to oversee operations, inspections, and safety practices.

- Stay Alert to Weather Changes: Rain, frost, or extreme heat can affect soil stability. Monitor weather conditions closely and adjust work plans as needed.

- Avoid Working Alone: Workers should avoid working in trenches alone. In case of an emergency, having others on-site ensures timely assistance and support.

Common Trenching and Excavation Hazards and How to Mitigate Them

To maintain a safe work environment, be aware of common hazards and take steps to mitigate them.

Table: Trenching Hazards and Mitigation Measures

| Hazard | Description | Mitigation Measure |

|---|---|---|

| Cave-ins | Trench walls collapse, trapping workers | Use shoring, sloping, or trench boxes |

| Hazardous Atmospheres | Toxic gases or low oxygen levels | Test air quality, ventilate if needed |

| Water Accumulation | Water destabilizes soil and trench walls | Pump out water or use drainage |

| Falling Objects | Equipment or tools fall into trench | Keep materials and equipment away from edges |

| Trips and Falls | Workers or bystanders falling into trench | Install barriers and warning signs |

Conclusion

Trenching and excavation work are high-risk tasks that require diligent planning, appropriate protective measures, and strict adherence to safety protocols. By following these essential tips, companies can significantly reduce the risks associated with trenching, protect their workers, and ensure compliance with occupational health and safety standards.

Proper training, regular inspections, and the use of protective systems create a safer working environment for everyone involved in trenching and excavation activities.

Ensuring that all workers follow these guidelines not only helps prevent accidents but also promotes a culture of safety that can make a lasting impact on the workplace.

No comments yet