Winter presents unique challenges for workers, particularly those operating outdoors or in unheated environments. Cold temperatures, icy conditions, and reduced visibility increase the risks of injuries and illnesses, making winter-specific personal protective equipment (PPE) essential.

Proper selection and use of PPE not only protect employees but also ensure productivity and comfort throughout the season.

The Importance of Winter PPE

Winter-specific personal protective equipment (PPE) is not just a luxury but a necessity for those exposed to harsh weather conditions. Standard PPE is not always sufficient in winter conditions. Prolonged exposure to cold can lead to hypothermia, frostbite, and reduced dexterity, all of which impair safety and performance.

Winter-specific PPE is designed to address these risks by providing insulation, maintaining flexibility, and enhancing visibility in low-light conditions. Employers must assess the work environment and tasks to select the most appropriate winter gear for their teams.

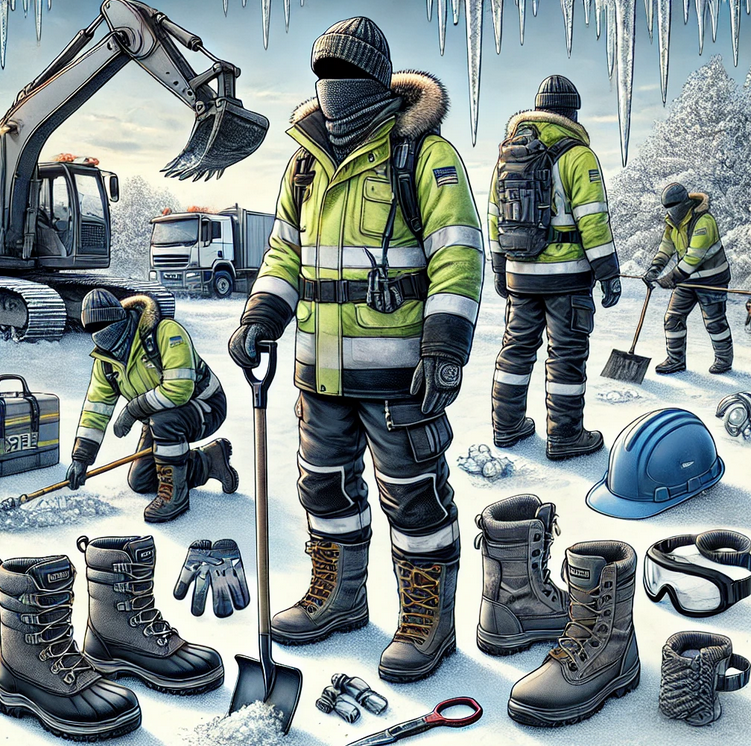

Key Types of Winter PPE

1. Insulated Gloves for Winter PPE

Hands are particularly vulnerable to cold temperatures, which can cause frostbite or impair motor skills. Insulated gloves are a must for winter work. Look for:

- Thermal insulation to retain warmth.

- Waterproof materials to prevent moisture from soaking through.

- Dexterity features for tasks requiring fine motor skills.

2. Thermal and Waterproof Footwear for Winter PPE

Feet are equally at risk during winter. Proper footwear prevents cold-related injuries and slips on icy surfaces. Key features include:

- Thick insulation for warmth.

- Anti-slip soles for traction on snow and ice.

- Waterproof linings to keep feet dry in wet conditions.

3. Layered Clothing Systems for Winter PPE

The foundation of winter PPE is a layered clothing system. It typically includes:

- Base layers made of moisture-wicking materials like merino wool to keep skin dry.

- Mid-layers for insulation, such as fleece or down.

- Outer layers that are windproof and waterproof to protect against the elements.

| Layer | Purpose | Recommended Materials |

|---|---|---|

| Base | Moisture management | Merino wool, synthetic blends |

| Mid | Insulation | Fleece, down |

| Outer | Weather protection | Windproof, waterproof fabrics |

4. Insulated Hard Hats for Winter PPE

For workers in construction or industries requiring head protection, insulated hard hats with liners are essential. They provide:

- Thermal insulation to prevent heat loss.

- Adjustable liners for a snug fit without compromising safety standards.

5. Eye and Face Protection in Winter PPE

Cold air, wind, and snow glare can irritate the eyes and skin. PPE for face and eye protection includes:

- Anti-fog safety goggles to maintain visibility.

- Balaclavas or face masks for full-face coverage.

- UV-protective eyewear to shield against snow glare.

6. High-Visibility Clothing for Winter PPE

Winter conditions often mean reduced visibility due to shorter daylight hours or snowstorms. High-visibility clothing ensures workers remain easily seen. Key elements include:

- Bright colors like neon yellow or orange.

- Reflective strips for added visibility in low-light environments.

7. Hearing Protection in Winter PPE

Cold weather can make ears more sensitive to noise. Workers in noisy environments should use earmuffs designed for winter, which combine hearing protection with insulation.

8. Respiratory Protection in Winter PPE

In extreme cold, respiratory systems can be strained. Masks or respirators designed for winter conditions ensure breathability while protecting against harmful particulates and cold air.

Selecting the Right Winter PPE

When choosing winter-specific PPE, employers should consider:

- Work environment: Is it wet, icy, or exposed to high winds?

- Task requirements: Does the job demand precision or heavy labor?

- Duration of exposure: How long will workers be exposed to the cold?

- Employee comfort: Uncomfortable gear may discourage proper use.

Involving employees in the selection process can also improve compliance and satisfaction with the equipment provided.

Maintenance and Storage of Winter PPE

Proper care of PPE ensures its longevity and effectiveness. Key practices include:

- Cleaning: Remove dirt, sweat, and other contaminants regularly.

- Inspection: Check for wear and tear, such as holes or compromised insulation.

- Storage: Keep PPE in a dry, well-ventilated area to prevent mold and damage.

Employers should provide guidelines and training on PPE maintenance to ensure workers understand its importance.

Training and Compliance for Winter PPE

Providing winter PPE is not enough; employees must be trained on its proper use. Training should cover:

- Correct donning and doffing techniques.

- Limitations of the equipment.

- Signs of cold-related illnesses and when to seek help.

Regular audits and feedback sessions can help ensure compliance and address any concerns about the equipment.

Notes on Effective Use of Winter PPE

- Layering: Ensure workers know how to layer clothing properly for optimal warmth.

- Hydration: Encourage hydration to maintain circulation and overall health.

- Breaks: Schedule regular breaks in warm areas to reduce prolonged exposure to the cold.

Examples of Industries Needing Winter PPE :

Winter PPE is essential across various industries where workers are exposed to extreme cold and wet conditions. For example, construction workers require insulated gloves and boots to maintain dexterity and safety on icy scaffolding.

Transportation employees, such as delivery drivers, need high-visibility jackets and thermal gear to stay visible and warm during snowstorms. Emergency responders often rely on specialized PPE to maintain mobility and comfort in freezing temperatures while performing rescues. Agricultural workers may also need waterproof clothing and insulated gloves to handle wet and cold tasks efficiently.

Common Challenges with Winter PPE :

Despite its importance, winter PPE can present challenges for both employers and workers. Balancing warmth with mobility is a common issue, as overly bulky gear may restrict movement and reduce efficiency. Workers may also experience discomfort if PPE is not properly fitted or if materials cause overheating during high-intensity tasks.

Additionally, high-quality winter PPE can be costly, and ensuring consistent supply and maintenance can strain budgets. Employers should seek solutions such as ergonomic designs, adjustable fits, and vendor negotiations for bulk discounts.

Technological Innovations in Winter PPE :

Recent advancements in technology have brought about innovative winter PPE solutions. Heated gloves and jackets equipped with battery-powered warming elements allow workers to remain comfortable even in sub-zero conditions. Advanced materials, like graphene and lightweight thermal fabrics, provide superior insulation without added bulk.

Smart PPE, including gear that monitors body temperature and environmental conditions, is becoming increasingly popular for enhancing safety and efficiency. Eco-friendly alternatives, such as recyclable thermal layers, are also gaining traction in workplaces committed to sustainability.

Legal Requirements and Standards for Winter PPE :

Adhering to legal standards for winter PPE is critical for workplace compliance. In Canada, the Canadian Centre for Occupational Health and Safety (CCOHS) provides guidelines for selecting and using PPE in cold environments. Similarly, OSHA in the United States outlines regulations to protect workers from cold stress and related hazards.

Employers should familiarize themselves with these standards to ensure that their PPE meets safety criteria. For example, thermal gloves and footwear must meet specific ratings for insulation and slip resistance.

Cost-Benefit Analysis of Winter PPE :

Investing in high-quality winter PPE can save costs in the long run by reducing workplace injuries and increasing productivity. While upfront expenses may seem significant, the financial losses from worker downtime, medical expenses, or legal penalties due to non-compliance are far greater.

Durable and well-maintained PPE can also reduce replacement costs over time. Employers can optimize budgets by purchasing versatile gear that serves multiple purposes, such as insulated clothing that doubles as rainproof protection.

Impact of Winter PPE on Productivity :

Winter PPE not only protects workers but also boosts their morale and productivity. Comfortable, well-insulated gear enables employees to focus on their tasks without the distraction of cold discomfort.

High-visibility clothing ensures that teams can work safely and efficiently in low-light conditions, such as early mornings or late evenings. By reducing the risk of cold-related illnesses and injuries, winter PPE helps maintain workforce continuity and operational efficiency during harsh weather.

Seasonal Maintenance and Replacement Schedules :

Proper maintenance of winter PPE ensures its effectiveness and longevity. Employers should establish a seasonal schedule for inspecting gear before the onset of winter. For example, insulated boots and gloves should be checked for wear and tear, and zippers or seams in jackets should be inspected for leaks.

Workers should be trained to clean and store their PPE correctly to prevent damage. Setting reminders for regular replacements, especially for high-use items, ensures that workers are always protected.

Environmental Factors and Site Assessments :

Conducting a winter hazard assessment is crucial for identifying site-specific risks. For example, icy walkways may require additional traction aids for workers’ boots, while high wind conditions may necessitate windproof outer layers.

Site assessments should also consider exposure duration, as tasks performed outdoors for extended periods increase the risk of hypothermia. Employers can use these evaluations to create tailored PPE guidelines and implement measures like installing temporary wind barriers.

Emergency Preparedness with Winter PPE :

Winter PPE plays a critical role in emergency preparedness, especially in extreme weather scenarios like blizzards or ice storms. Workers should have access to additional thermal layers, insulated blankets, and backup gloves in case of extended exposure to the cold.

Emergency kits can also include face masks and respirators to protect against windburn or inhalation of cold air. Training workers on using PPE effectively during emergencies ensures they can respond quickly and safely.

Visuals and Infographics :

Including visuals can make the article more engaging and informative. For example, diagrams showing proper layering of clothing can help readers understand how to combine base, mid, and outer layers effectively.

Infographics illustrating common winter hazards, such as frostbite or slips on ice, and their corresponding PPE solutions can enhance comprehension. Visual aids not only attract attention but also make complex information easier to digest.

Workplace Policy Recommendations :

Creating a clear policy for winter PPE usage ensures consistency and compliance. For example, a workplace policy might mandate wearing high-visibility jackets during outdoor tasks or require daily inspections of PPE for damage.

Employers can also outline procedures for reporting defective gear and obtaining replacements. A well-structured policy communicates the organization’s commitment to worker safety and sets clear expectations.

Conclusion

Winter-specific personal protective equipment (PPE) is vital for safeguarding employees in cold conditions. From insulated gloves to high-visibility jackets, each piece plays a role in minimizing risks and promoting comfort.

By investing in high-quality winter PPE and fostering a culture of safety, organizations can protect their workforce and maintain productivity throughout the winter months.

Employers should also consider consulting reliable resources like WorkSafeBC Winter Safety Guidelines and Canadian Centre for Occupational Health and Safety (CCOHS) for additional insights.

No comments yet