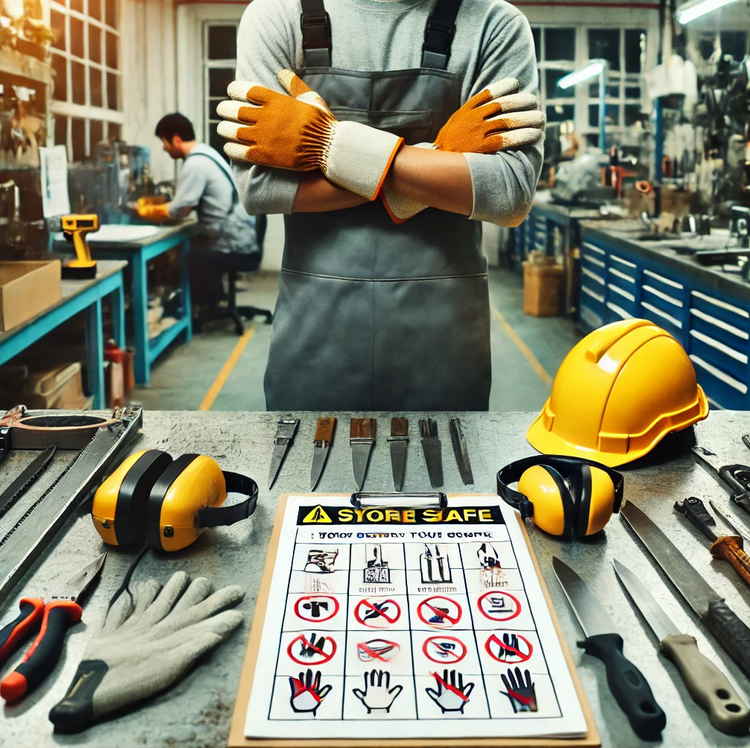

Preventing cuts and lacerations is critical for maintaining workplace safety and protecting employees from injuries that can lead to lost productivity, medical expenses, and long-term complications.

Whether working with sharp tools, machinery, or handling hazardous materials, understanding how to prevent cuts and lacerations is vital.

This article provides actionable strategies and tools to minimize risks and foster a safe working environment.

- 1. Why Preventing Cuts and Lacerations Is Important

- 2. Common Causes of Cuts and Lacerations

- 3. Preventing Cuts and Lacerations: Safety Tips

- 4. Training and Education for Preventing Cuts and Lacerations

- 5. Using Technology to Prevent Cuts and Lacerations

- 6. Responding to Cuts and Lacerations: First Aid and Emergency Steps

- 7. Benefits of Preventing Cuts and Lacerations

- 8. Challenges in Preventing Cuts and Lacerations

- 9. Future Trends in Preventing Cuts and Lacerations

- Conclusion

1. Why Preventing Cuts and Lacerations Is Important

Cuts and lacerations are among the most common workplace injuries, ranging from minor scrapes to severe wounds requiring medical attention. They not only pose risks to employee health but also impact overall operational efficiency.

Key Risks of Cuts and Lacerations:

- Exposure to infections and bloodborne pathogens.

- Reduced productivity due to recovery time.

- Increased operational costs from medical expenses and compensation claims.

Learn more about workplace injury statistics at OSHA (DoFollow link).

2. Common Causes of Cuts and Lacerations

2.1 Improper Use of Tools

- Using damaged or inappropriate tools increases the risk of accidents.

- Failure to follow safety guidelines while handling sharp objects.

2.2 Poor Workplace Organization

- Cluttered workspaces can lead to accidental contact with sharp edges.

- Inadequate storage of sharp tools and equipment.

2.3 Lack of Protective Gear

- Not wearing gloves or protective clothing exposes workers to unnecessary risks.

- Using the wrong type of PPE for the task at hand.

3. Preventing Cuts and Lacerations: Safety Tips

3.1 Proper Tool Maintenance

- Regularly inspect tools for damage or wear.

- Sharpen blades to ensure they function effectively and safely.

- Replace damaged tools immediately to avoid potential hazards.

3.2 Use Protective Equipment

- Wear cut-resistant gloves and sleeves for tasks involving sharp objects.

- Use aprons or other body coverings to protect exposed areas.

- Choose PPE appropriate to the level of risk.

Explore top-rated cut-resistant gloves at Safety+Health Magazine (DoFollow link).

3.3 Organize the Workspace

- Store sharp tools securely in designated areas.

- Keep walkways and work surfaces clear of clutter.

- Label hazardous zones and tools to increase awareness.

4. Training and Education for Preventing Cuts and Lacerations

4.1 Employee Training Programs

- Teach workers the correct methods for handling sharp tools and equipment.

- Include hands-on demonstrations for tasks requiring precision.

4.2 Safety Signage

- Post clear warning signs near areas with high risks of cuts or lacerations.

- Use visual aids to reinforce safety protocols.

4.3 Ongoing Refresher Courses

- Regularly update employees on new tools, technologies, and safety practices.

- Conduct periodic drills to reinforce safety awareness.

Discover training resources for workplace safety at National Safety Council (DoFollow link).

5. Using Technology to Prevent Cuts and Lacerations

5.1 Smart Safety Tools

- Invest in tools with built-in safety features, such as retractable blades.

- Use tools with sensors that automatically shut off when not in use.

5.2 Wearable Technology

- Equip workers with devices that monitor their movements and provide alerts for unsafe practices.

- Use wearable sensors to detect risks and improve ergonomic practices.

5.3 Automation

- Replace manual cutting tasks with automated systems where feasible.

- Use robotic arms for high-risk tasks to minimize human exposure.

6. Responding to Cuts and Lacerations: First Aid and Emergency Steps

6.1 Immediate First Aid

- Wash the wound thoroughly with soap and water.

- Apply pressure to stop bleeding and use a sterile bandage to cover the cut.

- Seek medical attention for deep or contaminated wounds.

6.2 Emergency Response Protocols

- Maintain a well-stocked first aid kit in the workplace.

- Train employees to recognize signs of serious injuries, such as excessive bleeding or infection.

6.3 Incident Reporting

- Document all incidents to identify patterns and improve safety measures.

- Use digital reporting tools for accurate and efficient tracking.

7. Benefits of Preventing Cuts and Lacerations

7.1 Improved Worker Health

- Reduced injuries mean fewer days lost to recovery and improved well-being.

7.2 Increased Productivity

- A safe workplace fosters confidence and efficiency among employees.

7.3 Enhanced Reputation

- Demonstrating a commitment to safety builds trust with clients and stakeholders.

8. Challenges in Preventing Cuts and Lacerations

8.1 Resistance to Safety Practices

Some workers may underestimate the risks or resist wearing protective gear. Overcome this by:

- Educating employees on the consequences of unsafe practices.

- Involving workers in selecting PPE for better acceptance.

8.2 Inadequate Safety Budgets

Investing in quality tools and training may seem costly initially but prevents larger expenses in the long run.

8.3 Dynamic Work Environments

Adapting safety measures to changing tasks and environments requires regular assessments and updates.

9. Future Trends in Preventing Cuts and Lacerations

9.1 Advanced Materials in PPE

Innovations in fabrics will lead to lighter, more comfortable cut-resistant gloves and clothing.

9.2 Artificial Intelligence

AI-powered systems will analyze workplace data to predict and prevent potential injuries.

9.3 Virtual Reality Training

VR simulations will provide immersive training experiences for high-risk tasks, improving worker preparedness.

Conclusion

Preventing cuts and lacerations is a shared responsibility that requires proactive measures, proper training, and a commitment to safety. By implementing these strategies, organizations can create a safer workplace, protect employees, and enhance overall efficiency.

Start prioritizing cut prevention today to ensure a secure and productive environment.

No comments yet