Manual handling safety in construction is a critical component of injury prevention that often goes overlooked. Construction workers are frequently exposed to lifting, carrying, pushing, and pulling heavy loads, which, when done improperly, can result in severe musculoskeletal injuries.

According to the Canadian Centre for Occupational Health and Safety (CCOHS), manual material handling is one of the most common sources of workplace injury, particularly in high-risk industries like construction.

Understanding how to apply safe handling techniques, leverage mechanical aids, and develop a safety-focused lifting culture can significantly reduce injuries and downtime.

This article will explore the hazards of poor manual handling, injury prevention strategies, and practical solutions to help construction crews lift smarter—not harder.

- Why Manual Handling Safety in Construction Matters

- Common Hazards in Manual Material Handling

- Principles of Safe Manual Handling

- Tools and Aids That Promote Smart Lifting

- Ergonomic Training and Worker Awareness

- Real-World Scenario: A Preventable Injury

- Legal Responsibilities and OHSE Compliance

- Conclusion: Make Lifting Smarter Your Site Standard

Why Manual Handling Safety in Construction Matters

Manual handling accounts for a significant portion of all construction-related injuries. Common injuries include:

- Back strains and sprains

- Herniated discs

- Shoulder injuries

- Knee and wrist damage

These injuries can lead to long-term disability, increased workers’ compensation claims, and loss of productivity. Manual handling safety in construction is not just a personal health issue—it’s a business-critical concern that affects the entire team.

Common Hazards in Manual Material Handling

Manual handling safety risks in construction arise from multiple sources. Workers are often exposed to:

- Improper lifting techniques like bending at the waist instead of the knees.

- Overexertion from lifting materials that exceed safe weight limits.

- Repetitive motions, especially when installing materials like drywall, bricks, or tiles.

- Awkward postures caused by confined spaces or uneven terrain.

- Carrying loads over long distances without rest or assistance.

These hazards are compounded by environmental factors such as weather conditions, poor lighting, or cluttered work areas.

Principles of Safe Manual Handling

1. Assess Before You Lift

Before lifting any object, evaluate:

- The weight and size of the load.

- The distance to be carried.

- Obstructions or uneven surfaces along the path.

- Whether assistance or mechanical aids are required.

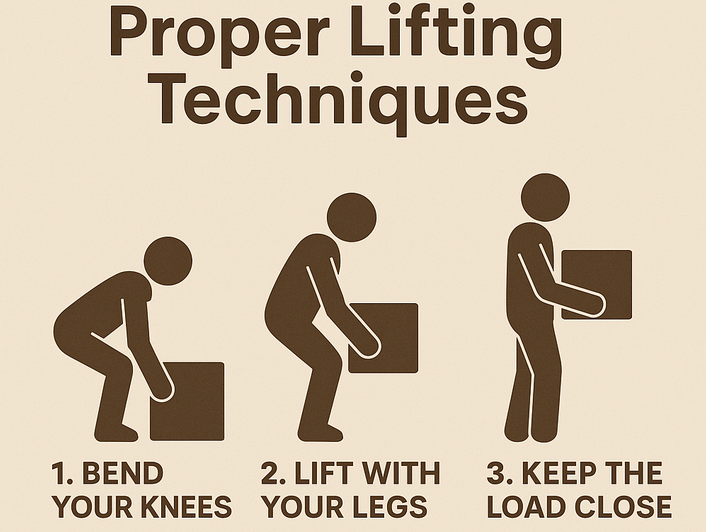

2. Use Proper Lifting Techniques

Encourage workers to follow these steps:

- Stand close to the object with feet shoulder-width apart.

- Bend at the knees, not the waist.

- Keep the back straight and core engaged.

- Use the legs to lift, not the back.

- Hold the load close to the body.

- Avoid twisting while lifting—pivot the feet instead.

3. Know Your Limits

Train workers to recognize their physical limitations. For example, WorkSafeBC recommends limiting manual lifting to loads under 23 kg (50 lbs) for most workers unless mechanical or team assistance is available.

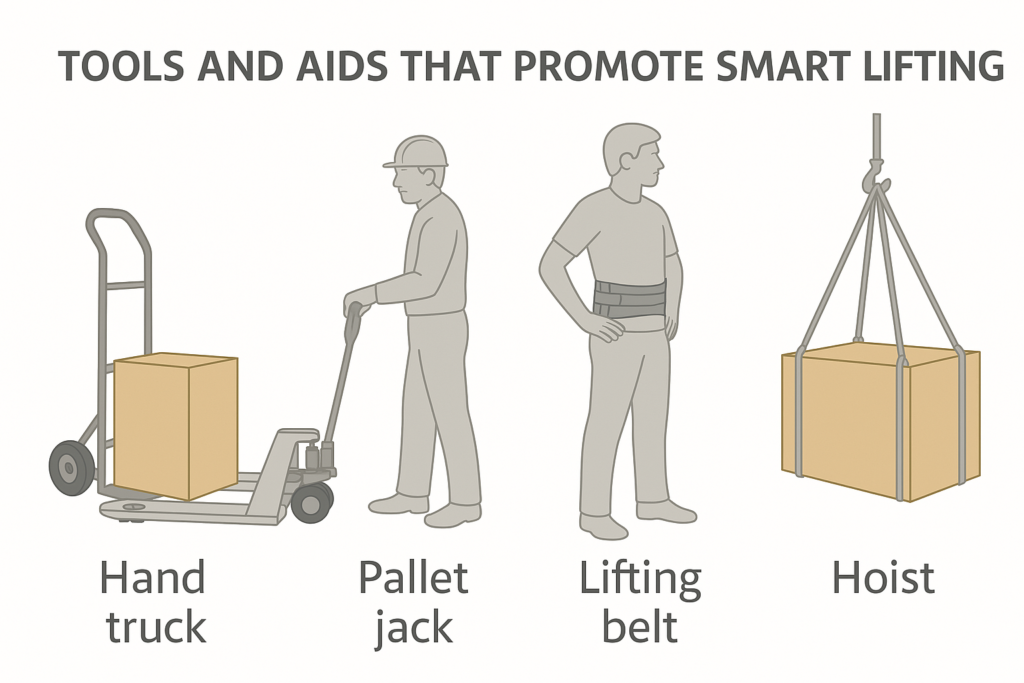

Tools and Aids That Promote Smart Lifting

To reduce risk, construction sites should be equipped with tools and mechanical aids that ease manual handling demands:

- Dollies, carts, and trolleys to transport heavy materials.

- Forklifts or skid steers for larger loads.

- Hoists and cranes for lifting materials to elevated surfaces.

- Vacuum lifters for glass, panels, and tiles.

- Lifting straps and adjustable harnesses to redistribute weight.

Investing in these aids reduces fatigue and injury while improving productivity.

Ergonomic Training and Worker Awareness

Manual handling safety in construction requires more than just equipment—it requires education and repetition.

- Conduct regular training on safe lifting and body mechanics.

- Use visual signage near storage areas to remind workers of proper technique.

- Incorporate manual handling modules into onboarding for new hires.

- Schedule stretching sessions or micro-breaks to reduce muscle strain.

Encourage workers to speak up about potential hazards or if they feel uncomfortable with a particular load.

Real-World Scenario: A Preventable Injury

A young construction laborer was helping unload cement bags weighing over 40 kg. Lacking proper instruction, he bent at the waist and twisted his torso while lifting.

After weeks of persistent lower back pain, he was diagnosed with a lumbar disc injury and placed on medical leave.

Post-incident investigation revealed no pre-lift assessment, no lifting training, and no use of team lifting policies.

After this event, the company implemented new safety protocols, including:

- Mandatory lifting safety training.

- Job rotation to reduce repetitive strain.

- Weight limit labels on material storage.

The injury could have been prevented by following basic manual handling safety in construction practices.

Legal Responsibilities and OHSE Compliance

In Canada, employers are required to provide a safe working environment under occupational health and safety regulations in each province and territory.

This includes:

- Identifying and assessing manual handling hazards.

- Providing necessary training and mechanical aids.

- Ensuring proper supervision and hazard communication.

Refer to CCOHS manual materials handling resources for more guidance on legal compliance and ergonomic principles.

Conclusion: Make Lifting Smarter Your Site Standard

Manual handling safety in construction must be a proactive, everyday practice. By combining training, proper technique, ergonomic equipment, and regular assessments, construction teams can reduce injuries, cut costs, and build a safety-driven culture.

Remember: it’s not about lifting harder—it’s about lifting smarter. Protect your back, protect your crew, and build a safer worksite from the ground up.

No comments yet