Confined spaces, often overlooked in workplace safety plans, present significant risks to workers across various industries. These spaces—such as tanks, silos, vaults, or underground pipelines—are not designed for continuous occupancy but may require entry for maintenance, inspection, or repairs.

Without proper precautions, confined spaces can become deadly environments. This article explores the unique hazards of confined spaces and outlines strategies to ensure worker safety.

1. What Is a Confined Space?

A confined space is defined by the following characteristics:

- Limited Entry and Exit: Access is restricted, making evacuation difficult in emergencies.

- Not Designed for Continuous Occupancy: These spaces are only entered for specific tasks.

- Potential Hazards: Confined spaces often contain physical or atmospheric risks.

Examples of Confined Spaces

- Storage tanks

- Underground sewers

- Crawl spaces

- Utility vaults

- Silos and grain bins

2. Common Hazards in Confined Spaces

A. Atmospheric Hazards

- Oxygen Deficiency: Levels below 19.5% can lead to dizziness, unconsciousness, or death.

- Toxic Gases: Presence of gases like hydrogen sulfide (H₂S), carbon monoxide (CO), or ammonia.

- Flammable Vapors: Vapors can ignite, causing explosions or fires.

B. Physical Hazards

- Engulfment: Materials like grain, sand, or liquids can engulf and suffocate workers.

- Mechanical Hazards: Moving parts or machinery within confined spaces.

- Structural Collapse: Unstable walls or ceilings in underground spaces.

C. Other Risks

- Extreme temperatures.

- Limited visibility.

- Psychological stress or claustrophobia.

3. Legal and Regulatory Requirements

Organizations must comply with local and international standards to ensure confined space safety. Key regulations include:

- OSHA (USA): 29 CFR 1910.146, which outlines procedures for permit-required confined spaces.

- CSA (Canada): Z1006 Management of Work in Confined Spaces.

- ISO: Standards such as ISO 45001 for occupational health and safety management.

4. Confined Space Entry Procedures

A. Pre-Entry Assessment

- Identify Hazards: Assess physical and atmospheric risks.

- Conduct Air Testing: Use calibrated gas detectors to measure oxygen levels and detect toxic or flammable gases.

- Develop a Permit: Include hazard assessment, required controls, and emergency procedures.

B. Establish a Safe Entry Plan

- Ventilation: Use mechanical blowers or exhaust fans to maintain safe air quality.

- Isolation: Lockout or tagout machinery to prevent accidental operation.

- Communication Systems: Provide radios or other devices to maintain contact between workers inside and outside.

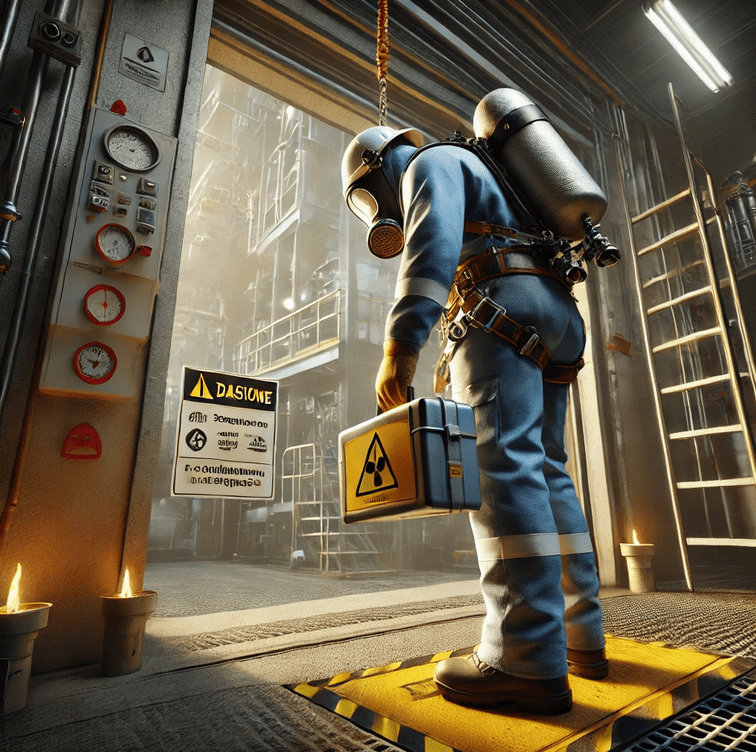

C. Provide Personal Protective Equipment (PPE)

- Respirators or self-contained breathing apparatus (SCBA) for hazardous atmospheres.

- Safety harnesses and lifelines for retrieval.

- Protective clothing suitable for the specific hazards.

D. Use a Trained Entry Team

- Entrants: Workers entering the confined space.

- Attendants: Individuals monitoring from outside, ready to initiate rescue.

- Supervisors: Responsible for ensuring compliance with safety procedures.

5. Emergency Response and Rescue

A. Key Elements of Rescue Plans

- Non-Entry Rescue: Utilize equipment like tripods, winches, or retrieval systems.

- Entry Rescue: If non-entry methods are insufficient, trained personnel may need to enter.

- Emergency Services: Coordinate with local fire departments or specialized rescue teams.

B. Rescue Equipment

- Tripods and winches for vertical spaces.

- Breathing apparatus for toxic environments.

- First aid kits and stretchers.

6. Preventive Measures

A. Training

- Educate workers on hazards, PPE use, and emergency procedures.

- Conduct regular drills to ensure readiness.

B. Monitoring

- Continuously monitor atmospheric conditions during confined space work.

- Use alarms to signal unsafe conditions.

C. Documentation

- Keep detailed records of permits, assessments, and training sessions.

- Conduct post-job reviews to identify and address gaps.

7. Case Study: Preventing a Confined Space Tragedy

Scenario:

A worker entered a chemical storage tank without proper testing or ventilation, resulting in fatal exposure to toxic gases.

Issues Identified:

- Lack of pre-entry air testing.

- No ventilation system in place.

- Inadequate training and absence of a rescue plan.

Corrective Actions:

- Implemented mandatory air quality testing.

- Installed ventilation systems for all tanks.

- Conducted comprehensive confined space safety training.

8. Conclusion

Confined spaces are inherently dangerous, but with proper planning, training, and adherence to safety protocols, risks can be mitigated. Employers must prioritize the safety of their workers by implementing rigorous procedures and equipping teams with the tools and knowledge needed to work safely. In confined spaces, vigilance and preparation are the keys to saving lives.

No comments yet